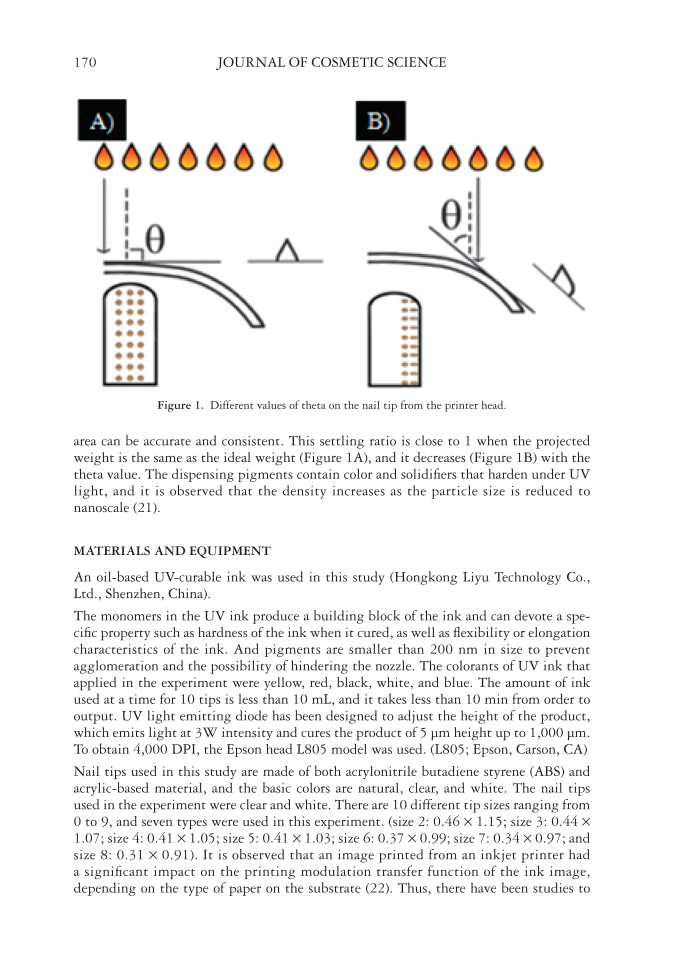

CONFORMAL PROJECTION PRINTING METHOD FOR 3D NAIL ART PRINTING 169 complement the operator’s skill level, reproducibility, low levels of precision, environ- mental hazards, and processes that are exposed to unsanitary and health risks in a long- term requirement (17). Recently, the introduction of technologies to eliminate health risks has begun. As one of the examples, in the fi eld of 3D printing, it was reported that the IoT-enabled 3D printers were controlled through web-cloud (18). This telemedicine system suc- cessfully delivered medicines with food (19). This concept has been extended to the 3D nail art area and with the convergence of IoT and AI technologies in conjunction with 3D printing or additive manufacturing. The applications have extended to beauty arts and cosmetics. The food has been controlled and printed through web- cloud with a single-line design technique (20). The applications have extended to beauty arts and cosmetics. In this study, an attempt was made to transmit a nail design to a web server where the customer could monitor the proceedings of the design and make changes. Customers can observe the results on the conformal surface of nails, and they can request modifi cation of the fi nal design. Even though hazardous chemicals, such as volatile organic compounds, have not been exposed to equipment operators and cus- tomers in the process, there were differences in the degree of completeness in the shape desired and the printed shape. The conformal projection printing method (CPPM) that was applied in this study demonstrated that not only high precision but also increased environmental safety level shortened the processing time and the modifi cation and supplementation of the printing process required by consumers in the worksite. The simulation between the laser beam and nail in different numbers of printings were performed through repeated experiments with the CPPM. The technique that was introduced at the time required to print 10 nail shapes on the system, and it took 10 min from the order to the fi nal result. Validation experiments have been carried out on a logistics system that allows the customer to order specialized nail designs directly on the web and to modify the results from anywhere in the world. The study presents the ability to print 300- 4,000 dots per inch (DPI) with high defi nition, which is superior to the conventional manual method of nail art. It is expected that 3D printing technology, which shows high sharpness results and a three-dimensional effect, can adjust the height to more than 2–5 μm, and can be combined with nail art technology to lead contemporary markets and technologies. ME THODS CP PM CP PM was applied in the fi eld of nail art. Figure 1 shows the angle of incidence (theta, θ) formed between the projected line and the surface of the nail tip. The weight of ink pro- jected perpendicular to the surface per unit area of the nail is called the ideal weight and is denoted as WI, whereas the weight of ink projected on the conformal surface per unit area of the nail is called the projected weight and is denoted by WP. Overall, based on the actual projected amount per unit area, the range of theta is Rb 0 90°, ° and the settling ratio is b1. 0 P I W W According to the formula sinR, P I W W the projected quantity per unit

JOURNAL OF COSMETIC SCIENCE 170 area can be accurate and consistent. This settling ratio is close to 1 when the projected weight is the same as the ideal weight (Figure 1A), and it decreases (Figure 1B) with the theta value. The dispensing pigments contain color and solidifi ers that harden under UV light, and it is observed that the density increases as the particle size is reduced to nanoscale (21). MATERI A LS AND EQUIPMENT An oil -based UV-curable ink was used in this study (Hongkong Liyu Technology Co., Ltd., Shenzhen, China). The mo nomers in the UV ink produce a building block of the ink and can devote a spe- cifi c property such as hardness of the ink when it cured, as well as fl exibility or elongation characteristics of the ink. And pigments are smaller than 200 nm in size to prevent agglomeration and the possibility of hindering the nozzle. The colorants of UV ink that applied in the experiment were yellow, red, black, white, and blue. The amount of ink used at a time for 10 tips is less than 10 mL, and it takes less than 10 min from order to output. UV light emitting diode has been designed to adjust the height of the product, which emits light at 3W intensity and cures the product of 5 μm height up to 1,000 μm. To obtain 4,000 DPI, the Epson head L805 model was used. (L805 Epson, Carson, CA) Nail tips used in this study are made of both acrylonitrile butadiene styrene (ABS) and acrylic-based material, and the basic colors are natural, clear, and white. The nail tips used in the experiment were clear and white. There are 10 different tip sizes ranging from 0 to 9, and seven types were used in this experiment. (size 2: 0.46 × 1.15 size 3: 0.44 × 1.07 size 4: 0.41 × 1.05 size 5: 0.41 × 1.03 size 6: 0.37 × 0.99 size 7: 0.34 × 0.97 and size 8: 0.31 × 0.91). It is observed that an image printed from an inkjet printer had a signifi cant impact on the printing modulation transfer function of the ink image, depending on the type of paper on the substrate (22). Thus, there have been studies to Figure 1. Different values of theta on the nail tip from the printer head.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)