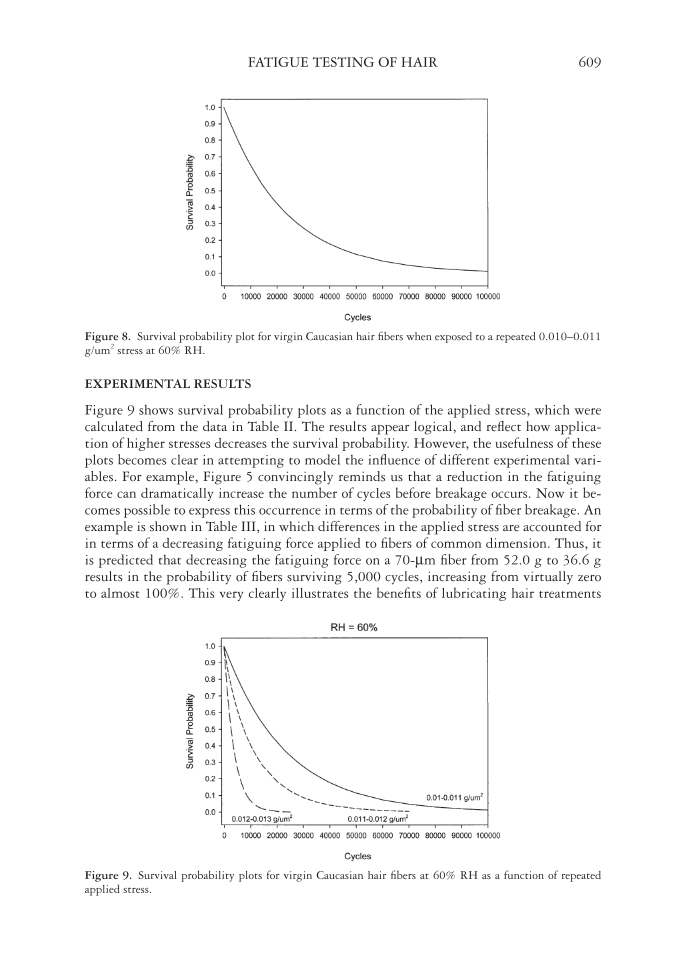

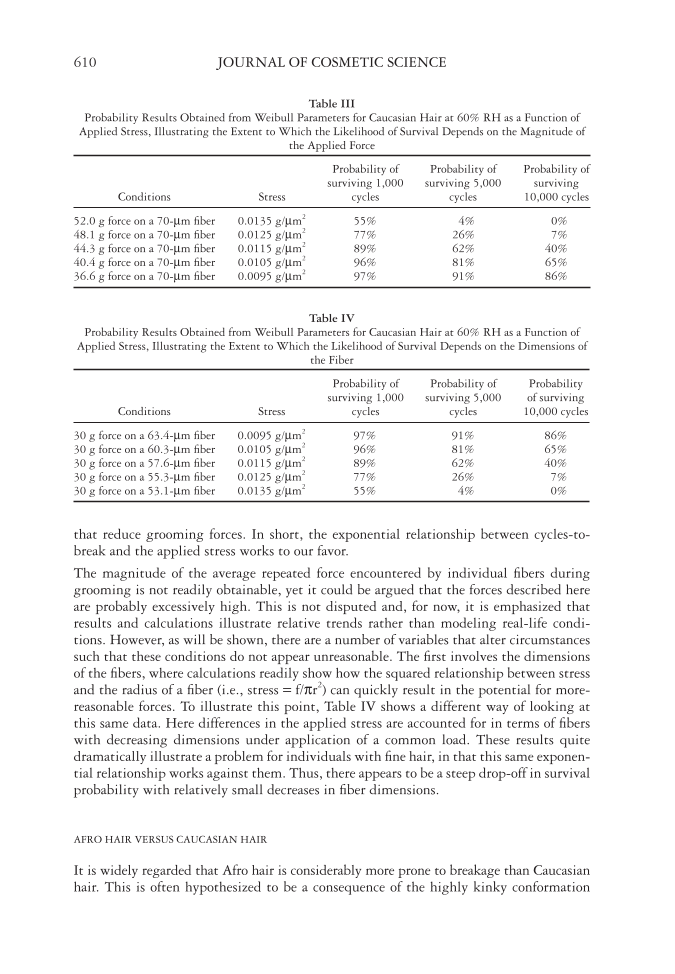

FATIGUE TESTING OF HAIR 609 EXPERIMENTAL RESULTS Figure 9 shows survival probability plots as a function of the applied stress, which were calculated from the data in Table II. The results appear logical, and refl ect how applica- tion of higher stresses decreases the survival probability. However, the usefulness of these plots becomes clear in attempting to model the infl uence of different experimental vari- ables. For example, Figure 5 convincingly reminds us that a reduction in the fatiguing force can dramatically increase the number of cycles before breakage occurs. Now it be- comes possible to express this occurrence in terms of the probability of fi ber breakage. An example is shown in Table III, in which differences in the applied stress are accounted for in terms of a decreasing fatiguing force applied to fi bers of common dimension. Thus, it is predicted that decreasing the fatiguing force on a 70-μm fi ber from 52.0 g to 36.6 g results in the probability of fi bers surviving 5,000 cycles, increasing from virtually zero to almost 100%. This very clearly illustrates the benefi ts of lubricating hair treatments Figure 8. Survival probability plot for virgin Caucasian hair fi bers when exposed to a repeated 0.010–0.011 g/um2 stress at 60% RH. Figure 9. Survival probability plots for virgin Caucasian hair fi bers at 60% RH as a function of repeated applied stress.

JOURNAL OF COSMETIC SCIENCE 610 that reduce grooming forces. In short, the exponential relationship between cycles-to- break and the applied stress works to our favor. The magnitude of the average repeated force encountered by individual fi bers during grooming is not readily obtainable, yet it could be argued that the forces described here are probably excessively high. This is not disputed and, for now, it is emphasized that results and calculations illustrate relative trends rather than modeling real-life condi- tions. However, as will be shown, there are a number of variables that alter circumstances such that these conditions do not appear unreasonable. The fi rst involves the dimensions of the fi bers, where calculations readily show how the squared relationship between stress and the radius of a fi ber (i.e., stress = f/πr2) can quickly result in the potential for more- reasonable forces. To illustrate this point, Table IV shows a different way of looking at this same data. Here differences in the applied stress are accounted for in terms of fi bers with decreasing dimensions under application of a common load. These results quite dramatically illustrate a problem for individuals with fi ne hair, in that this same exponen- tial relationship works against them. Thus, there appears to be a steep drop-off in survival probability with relatively small decreases in fi ber dimensions. AFRO HAIR VERSUS CAUCASIAN HAIR It is widely regarded that Afro hair is considerably more prone to breakage than Caucasian hair. This is often hypothesized to be a consequence of the highly kinky conformation Table III Probability Results Obtained from Weibull Parameters for Caucasian Hair at 60% RH as a Function of Applied Stress, Illustrating the Extent to Which the Likelihood of Survival Depends on the Magnitude of the Applied Force Conditions Stress Probability of surviving 1,000 cycles Probability of surviving 5,000 cycles Probability of surviving 10,000 cycles 52.0 g force on a 70-μm fi ber 0.0135 g/μm2 55% 4% 0% 48.1 g force on a 70-μm fi ber 0.0125 g/μm2 77% 26% 7% 44.3 g force on a 70-μm fi ber 0.0115 g/μm2 89% 62% 40% 40.4 g force on a 70-μm fi ber 0.0105 g/μm2 96% 81% 65% 36.6 g force on a 70-μm fi ber 0.0095 g/μm2 97% 91% 86% Table IV Probability Results Obtained from Weibull Parameters for Caucasian Hair at 60% RH as a Function of Applied Stress, Illustrating the Extent to Which the Likelihood of Survival Depends on the Dimensions of the Fiber Conditions Stress Probability of surviving 1,000 cycles Probability of surviving 5,000 cycles Probability of surviving 10,000 cycles 30 g force on a 63.4-μm fi ber 0.0095 g/μm2 97% 91% 86% 30 g force on a 60.3-μm fi ber 0.0105 g/μm2 96% 81% 65% 30 g force on a 57.6-μm fi ber 0.0115 g/μm2 89% 62% 40% 30 g force on a 55.3-μm fi ber 0.0125 g/μm2 77% 26% 7% 30 g force on a 53.1-μm fi ber 0.0135 g/μm2 55% 4% 0%

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)