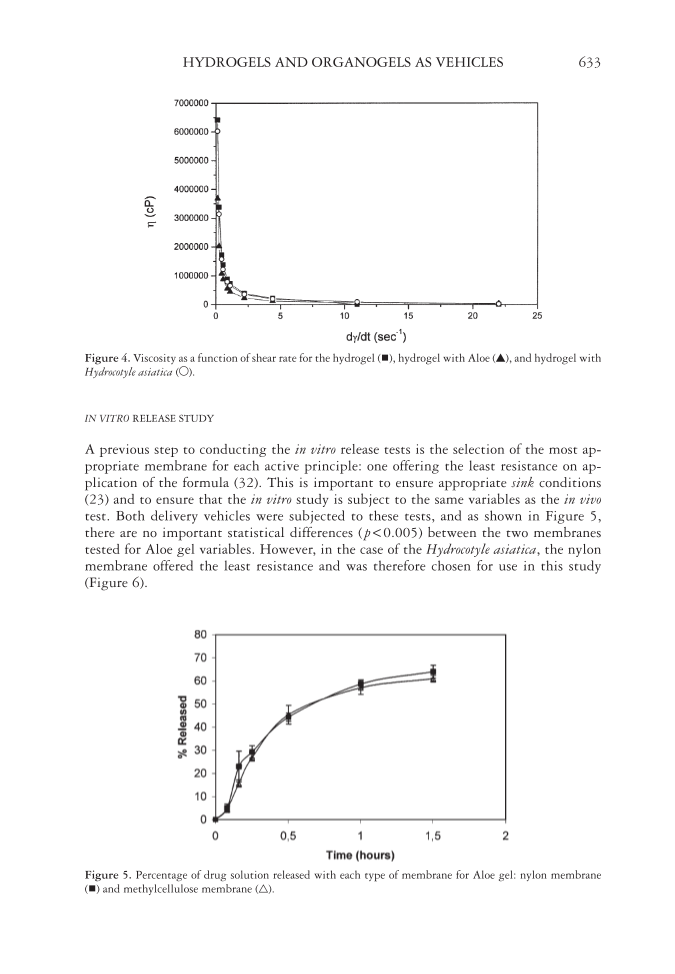

HYDROGELS AND ORGANOGELS AS VEHICLES 633 Figure 4. Viscosity as a function of shear rate for the hydrogel ( ), hydrogel with Aloe (▲), and hydrogel with Hydrocotyle asiatica (○). IN VITRO RELEASE STUDY A previous step to conducting the in vitro release tests is the selection of the most ap- propriate membrane for each active principle: one offering the least resistance on ap- plication of the formula (32). This is important to ensure appropriate sink conditions (23) and to ensure that the in vitro study is subject to the same variables as the in vivo test. Both delivery vehicles were subjected to these tests, and as shown in Figure 5, there are no important statistical differences ( p 0.005) between the two membranes tested for Aloe gel variables. However, in the case of the Hydrocotyle asiatica, the nylon membrane offered the least resistance and was therefore chosen for use in this study (Figure 6). Figure 5. Percentage of drug solution released with each type of membrane for Aloe gel: nylon membrane ( ) and methylcellulose membrane ( ).

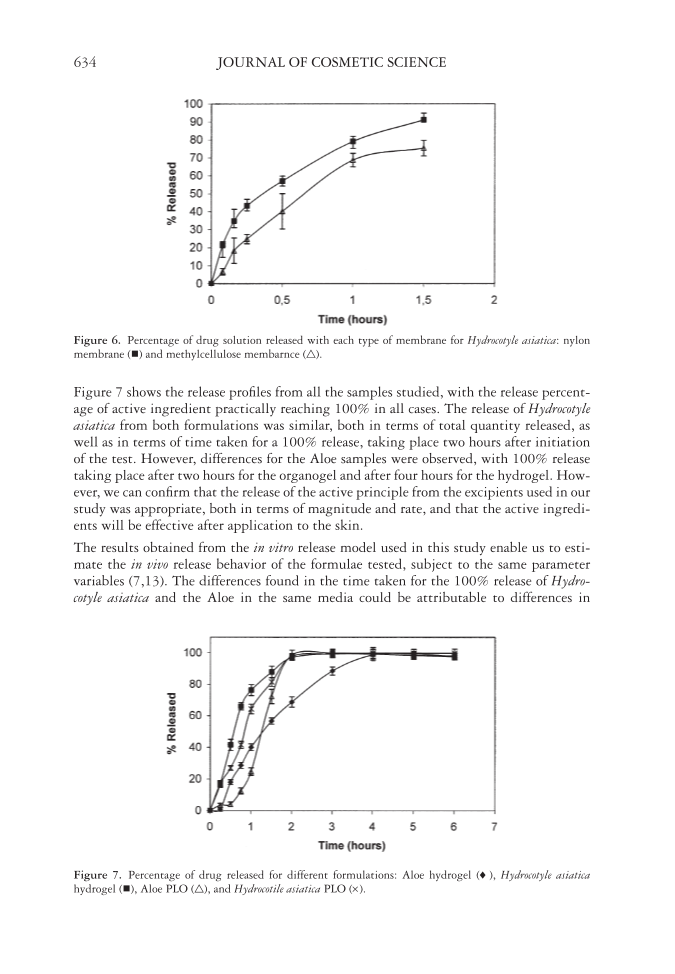

JOURNAL OF COSMETIC SCIENCE 634 Figure 7 shows the release profi les from all the samples studied, with the release percent- age of active ingredient practically reaching 100% in all cases. The release of Hydrocotyle asiatica from both formulations was similar, both in terms of total quantity released, as well as in terms of time taken for a 100% release, taking place two hours after initiation of the test. However, differences for the Aloe samples were observed, with 100% release taking place after two hours for the organogel and after four hours for the hydrogel. How- ever, we can confi rm that the release of the active principle from the excipients used in our study was appropriate, both in terms of magnitude and rate, and that the active ingredi- ents will be effective after application to the skin. The results obtained from the in vitro release model used in this study enable us to esti- mate the in vivo release behavior of the formulae tested, subject to the same parameter variables (7,13). The differences found in the time taken for the 100% release of Hydro- cotyle asiatica and the Aloe in the same media could be attributable to differences in Figure 6. Percentage of drug solution released with each type of membrane for Hydrocotyle asiatica: nylon membrane ( ) and methylcellulose membarnce ( ). Figure 7. Percentage of drug released for different formulations: Aloe hydrogel (♦), Hydrocotyle asiatica hydrogel ( ), Aloe PLO ( ), and Hydrocotile asiatica PLO (×).

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)