PREFORMULATION STUDIES OF PEPTIDES KTTKS AND PAL-KTTKS 301 behavior, aqueous solubility, partition coeffi cient, surface activity, critical micelle concen- tration (CMC), and aqueous stabilities were evaluated. The results should be useful for formulation development and also will provide information on palmitic acid conjugation of peptides, possibly useful for peptides other than KTTKS. MATERIA L AND METHOD MATERIA LS 2-chlor otrityl chloride resin (loading capacity of 1.2 mmol/g), Fmoc-Ser(tBu)-OH, Fmoc-Thr(tBu)-OH, Fmoc-Lys(Boc)-OH, and 2-(7Aza-1H-benzotriazol-1-yl)-1,1,3,3- tetramethyluronium hexafluorophosphate (HATU) were provided by GL Biochem (Shanghai, China). Trifl uoroacetic acid and piperidine were obtained from Exir GmbH (Wien, Austria). Ninhydrin was purchased from BDH Chemicals (Lutterworth, England). Isopropyl alcohol was supplied by ChemLab (Zedelgem, Belgium). Other solvents and reagents applied in the peptide synthesis process were purchased from Sigma-Aldrich (Dorset, United Kingdom) or Merck (Gernsheim, Germany). All materials were used without further purifi cation. METHODS Peptide synthesis and characterization. KTTKS an d Pal-KTTKS were synthesized by solid- phase peptide synthesis (SPPS) using the standard fl uorenylmethyloxycarbonyl (Fmoc) strategy in a manual glass reaction vessel (9). The 2-chlorotrityl chloride resin was ap- plied as an insoluble support, and to protect side chain reaction during the process, amino acids containing tert-butyloxycarbonyl (Boc) or tert-butyl side-chain protecting groups were used. After synthesis, confi rmation of peptide integrity was accomplished by mass spectroscopy using an Agilent 6410 Triple Quad LC/MS (Agilent, Santa Clara, CA) with an electrospray ionization interface. Determin ation of UV absorbance. Aqueous solutions of KTTKS and Pal-KTTKS were pre- pared individually. First, UV absorbance was set to zero with deionized water, and the solvent of peptide solution was used as the blank. UV absorbance of solutions was then measured over the wavelength range of 190–400 nm by a Cecil 2021 UV-Visible spectro- photometer (Cecil Instrument Services, Cambridge, United Kingdom) using a quartz cuvette with a 1-cm path length. Evaluati on of particle morphology by SEM. The morp hology of KTTKS and Pal-KTTKS was analyzed by SU3500 scanning electron microscopy (Hitachi Ltd., Tokyo, Japan) at an ac- celerating voltage of 15 kV. Peptide powders were mounted on a stub of metal with ad- hesive, coated with gold, and then analyzed by SEM. Evaluati on of birefringence under polarized light microscopy. Birefrin gence was examined using a CETI Magnum binocular compound microscope (Medline Scientifi c, Oxford, United Kingdom) with a total magnifi cation of 100×. The glass slide of each peptide powder was prepared and observed under cross-polarized light at ambient temperature. Structure evaluation by X-ray diffraction (XRD). XRD patte rns of KTTKS, Pal-KTTKS, and palmitic acid were measured using an X-ray diffractometer (X’Pert Pro MPD,

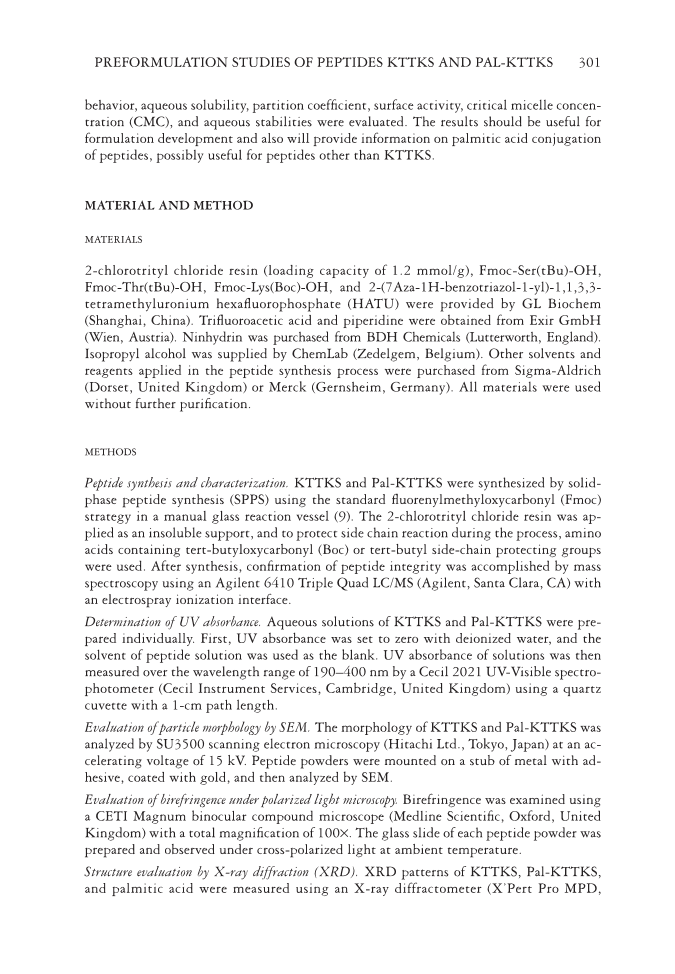

JOURNAL OF COSMETIC SCIENCE 302 Panalytical B.V, Almelo,The Netherlands) at laboratory temperature (25°C) under the following conditions: voltage of 40 kV, current of 40 mA, and scan range of 1–80 2θ using Cu Kα radiation. Partitioning and solubility investigation. The n-octanol/water partition coeffi cient ( w Po) was ob- tained using the shake fl ask method for KTTKS and partition coeffi cient and solubility of Pal-KTTKS were computed using ACD/ChemSketch (ACD/Labs, Toronto, Canada) and ALOGPS (VCC-LAB, Munich, Germany) programs (10–12). In the shake fl ask method, n-octanol and distilled water were mutually saturated with each other for 24 h before use. KTTKS was dissolved in water presaturated with n-octanol at a concentration of 200 μg/mL. In the following, n-octanol, presaturated with water, was added to the glass vials containing the aqueous solution of peptide. The glass vials were mixed by vortex for 2 min and then placed on an orbital shaker for 1 h to achieve equili- bration. To separate the phases, contents of the glass vials were transferred to a separation funnel and left without shaking for 0.5 h. The phases were separated and concentrations of peptide in the aqueous phase were measured by LC–MS, as described in the Peptide assay by LC-MS section. The n-octanol/water partition coeffi cient was then calculated us- ing equation 1 (13): o logP log , o w w C C (1) where Co a nd Cw are the concentrations of peptide in n-octanol and water after equilibra- tion, respectively. The experiment was performed in triplicate. Aqueous solubil ity of KTTKS was estimated by adding increasing amounts of peptide to a certain volume of distilled water at room temperature. Surface tension measurement of peptide solutions. Surface tension s of aqueous solutions of KTTKS and Pal-KTTKS (prepared individually with concentrations of 100 μg/mL) as well as deionized water were measured by a K100 Force tensiometer (Krüss GmbH, Hamburg, Germany) using the Du Noüy ring method at room temperature. In addition, the surface tensions of both peptides and also deionized water were calculated by the ACD/ChemSketch freeware software. This software calculates the surface tension via molar volume and parachor (14). Determination of C MC. Aqueous solution o f Pal-KTTKS was prepared using deionized water. The CMC value was then measured fully automatically by the K100 Force tensi- ometer (with one micro dispenser) using the Du Noüy ring method at room temperature. The measurement was repeated three times. Thermal behavior. Th ermal behaviors of peptides were evaluated by IA9000 series capillary melting apparatus (Cole-Parmer Instrument, Vernon Hills, IL), TGA-50, and DSC-60 (Shimadzu, Kyoto, Japan) thermal analysis systems. The melting point apparatus was used to determine the melting points. The capillary tube was packed by gently pressing the open end into the peptide powders. The bottom of the capillary tube was then tapped on a hard surface so that the peptide powders packed down into the bottom of the capillary tube. The capillary tubes containing the peptide powder were inserted into the apparatus holder. Ramp rate of 5°C/min was adjusted. The peptide powders were then examined through the magnifying glass of the apparatus, and changes in the powder bed were recorded during the temperature rise.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)