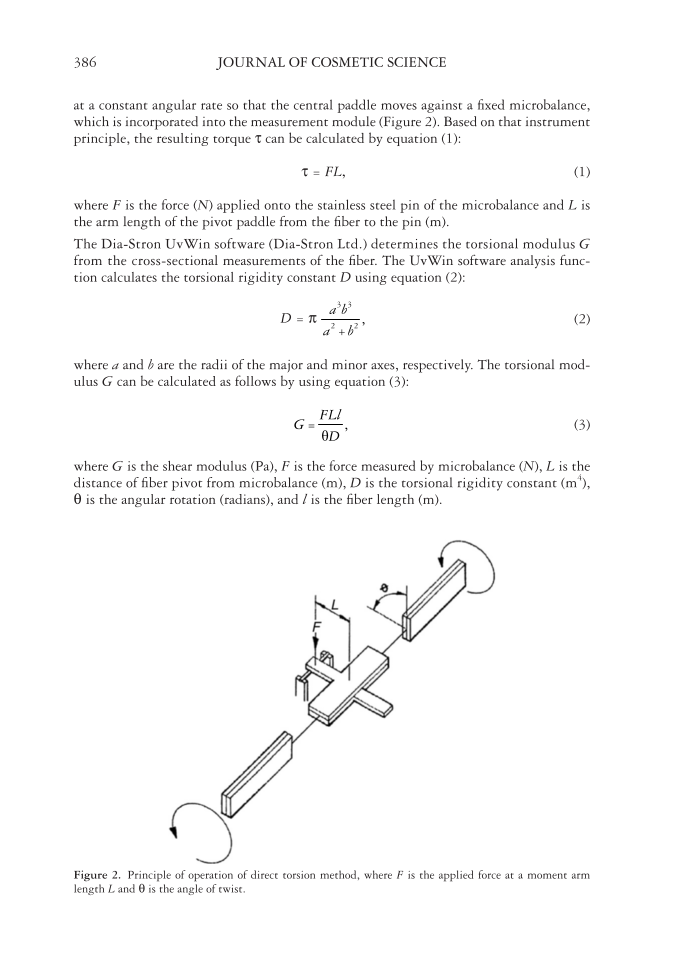

JOURNAL OF COSMETIC SCIENCE 386 at a constant angular rate so that the central paddle moves against a fi xed microbalance, which is incorporated into the measurement module (Figure 2). Based on that instrument principle, the resulting torque τ can be calculated by equation (1): τ = FL, (1) where F is the force (N) applied onto the stainless steel pin of the microbalance and L is the arm length of the pivot paddle from the fi ber to the pin (m). The Dia-Stron UvWin software (Dia-Stron Ltd.) determines the torsional modulus G from the cross-sectional measurements of the fi ber. The UvWin software analysis func- tion calculates the torsional rigidity constant D using equation (2): D = π 3 2 , +b2 a b3 a (2) w here a and b are the radii of the major and minor axes, respectively. The torsional mod- ulus G can be calculated as follows by using equation (3): șD = , FLl G (3) wh ere G is the shear modulus (Pa), F is the force measured by microbalance (N), L is the distance of fi ber pivot from microbalance (m), D is the torsional rigidity constant (m4), θ is the angular rotation (radians), and l is the fi ber length (m). Fig ure 2. Principle of operation of direct torsion method, where F is the applied force at a moment arm length L and θ is the angle of twist.

QUASI-STATIC TORSIONAL DEFORMATION OF SINGLE HAIR FIBERS 387 MATERIALS AND METHODS PREPARATION OF THE HAIR Dark brown European hair was obtained from International Hair Importers and Prod- ucts (Glendale, NY). Before any treatments, the swatches were washed with a 14% solution of sodium laureth sulfate (SLES), rinsed, and allowed to dry under controlled environmental conditions. For the studies requiring bleached hair, the swatches were bleached using a basic commercial bleach powder and 12% hydrogen peroxide for 60 min at 30°C before rinsing with warm water and dried with a hair drier set to 55°C. The swatches were allowed to equilibrate at 20°C and 50% relative humidity (RH) for 2 h in between bleaching cycles. The swatches were either bleached for two or three cycles dependent on the study. Individual fi bers were selected at random from the swatch and mounted between two 2-part plastic tabs to give a gauge length of 30 mm. A plastic torsion tab of length 14 mm was mounted and attached to the central section of the fi ber leaving two 8-mm test length sections. For the studies carried out on double bleached hair treated with a market leading com- mercial shampoo and conditioner system, the swatches were fi rst washed with 0.2 g of shampoo per gram of hair and rinsed for 30 s. This was followed by applying 0.1 g of the conditioner per gram of hair for 60 s and rinsed for 30 s. For the studies carried out on double bleached hair treated with Abyssinian oil (Crambe Abyssinica Seed Oil, Elementis), the premounted fi bers (without the central torsion tab) were immersed in the oil for 5 min taking care not to immerse the end tabs in the oil. The fi bers were then rinsed for 60 s in deionized water and then washed with a 5% SLES solution to remove any excess oil. For both treatments, the specimens were allowed to dry overnight under controlled environmental conditions. FIBER DIMENSIONAL ANALYSIS After sample preparation at equilibration at 50% RH and 20°C, the fi ber dimensions were measured with an automated Dia-Stron FDAS770. Six data slices, one rotation per slice, were collected for each specimen with three slices being taken on either side of the cen- trally mounted torsion tab. The maximum and minimum fi ber diameters per slice are obtained, with the averages across each slice being used in the calculations. TORSIONAL EXPERIMENTS The torsional properties of each fi ber were measured using an automated Dia-Stron FTT950. The fi bers were subjected to a pretension force of 10 g at a linear extension rate of 10 mm/min. From this, it is possible to obtain the tensile elastic modulus, although this was not recorded for all of these studies. A torsional gauge force of 2 mg was applied and the fi ber specimens were rotated through an angle of 90° at a rate of 5°/s. All fi bers were equili- brated at the required environmental conditions for at least 2 h before the measurements were taken.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)