JOURNAL OF COSMETIC SCIENCE 364 bleaching reagents most often used are aqueous solutions of hydrogen peroxide adjusted to pH values between 9 and 11. In bleaching compositions, persulfate salts are often added as accelerators (3,4). A published work on hair fragrance persistence from Blakeway and Seu-Salerno (5) ob- served the high affi nity of amyl salicylate to virgin hair remaining for over 24 h after deposition. According to the authors, the fragrance transference to hair occurs as a parti- tion mechanism of organic molecules from water phase to hair keratin, a mainly nonpolar support, and the fragrance persistence on hair depends on the molecule polarity. The present article contributes to the comprehension of the capacity of fragrance deposition on bleached hair by washing in comparison with the virgin hair and compares the fragrance liberation after drying to the desorption of moisture on hair before and after bleaching. MATERIALS AND METHODS SAMPLES Caucasian virgin dark brown hair, 25-cm long, was purchased from International Hair Importers (New York, NY). The hair tresses were washed with a 2.0% w/w sodium lauryl sulfate aqueous solution and left to dry at room temperature for at least 24 h. BLEACHING TREATMENT Hair tresses underwent bleaching for 10, 20, and 40 min with a hydrogen peroxide solu- tion (4.5% v/v pH = 9.5 at 55°C), consisting of 15% (w/w) of ammonium persulfate, and 70% of distilled water. The pH was reached using a concentrated sodium hydroxide solution (6). After the bleaching treatment, the samples were rinsed with tap water for 2 min and left to dry at room temperature. DIFFERENTIAL SCANNING CALORIMETRY (DSC) ANALYSIS Amounts of 5–7 mg of hair, approximately 0.5-cm long, were cut and placed in pressure- resistant stainless steel capsules. Fifty microliters of deionized water was introduced. The instrument used was DSC 4000 (PerkinElmer, Waltham, MA). The temperature range was from 70°C to 180°C, with a heating rate of 5°C min-1. The samples of hair were stored overnight at an environment with 20°C ± 2°C and 50% ± 5% of relative humidity to ensure constant water content. The capsules were sealed and stored for 24 h before test run. FLUORESCENCE MICROSCOPY Small portions of hair fi bers, about 3 cm long, collected from the swatches were embedded in acrylic resin. Sectional 10-μm cuts were processed with the use of a microtome. The cuts were exposed to rhodamine B (Sigma-Aldrich, St. Louis, MO) solution (10 μg mL-1)

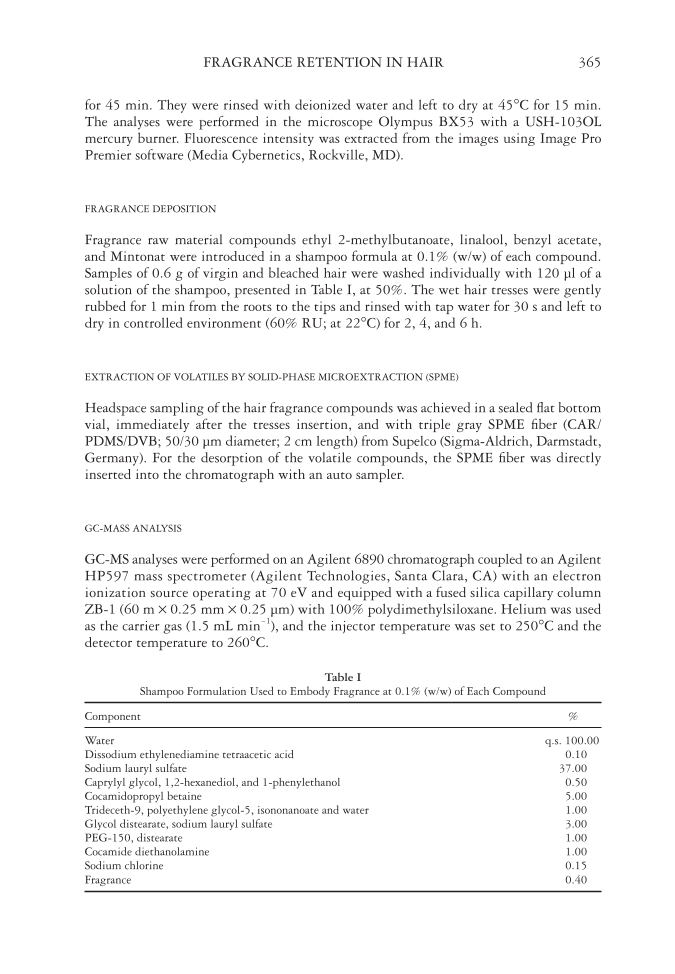

FRAGRANCE RETENTION IN HAIR 365 for 45 min. They were rinsed with deionized water and left to dry at 45°C for 15 min. The analyses were performed in the microscope Olympus BX53 with a USH-103OL mercury burner. Fluorescence intensity was extracted from the images using Image Pro Premier software (Media Cybernetics, Rockville, MD). FRAGRANCE DEPOSITION Fragrance raw material compounds ethyl 2-methylbutanoate, linalool, benzyl acetate, and Mintonat were introduced in a shampoo formula at 0.1% (w/w) of each compound. Samples of 0.6 g of virgin and bleached hair were washed individually with 120 μl of a solution of the shampoo, presented in Table I, at 50%. The wet hair tresses were gently rubbed for 1 min from the roots to the tips and rinsed with tap water for 30 s and left to dry in controlled environment (60% RU at 22°C) for 2, 4, and 6 h. EXTRACTION OF VOLATILES BY SOLID-PHASE MICROEXTRACTION (SPME) Headspace sampling of the hair fragrance compounds was achieved in a sealed fl at bottom vial, immediately after the tresses insertion, and with triple gray SPME fi ber (CAR/ PDMS/DVB 50/30 μm diameter 2 cm length) from Supelco (Sigma-Aldrich, Darmstadt, Germany). For the desorption of the volatile compounds, the SPME fi ber was directly inserted into the chromatograph with an auto sampler. GC-MASS ANALYSIS GC-MS analyses were performed on an Agilent 6890 chromatograph coupled to an Agilent HP597 mass spectrometer (Agilent Technologies, Santa Clara, CA) with an electron ionization source operating at 70 eV and equipped with a fused silica capillary column ZB-1 (60 m × 0.25 mm × 0.25 μm) with 100% polydimethylsiloxane. Helium was used as the carrier gas (1.5 mL min-1), and the injector temperature was set to 250°C and the detector temperature to 260°C. Table I Shampoo Formulation Used to Embody Frag rance at 0.1% (w/w) of Each Compound Component % Water q.s. 100.00 Dissodium ethylenediamine tetraacetic acid 0.10 Sodium lauryl sulfate 37.00 Caprylyl glycol, 1,2-hexanediol, and 1-phenylethanol 0.50 Cocamidopropyl betaine 5.00 Trideceth-9, polyethylene glycol-5, isononanoate and water 1.00 Glycol distearate, sodium lauryl sulfate 3.00 PEG-150, distearate 1.00 Cocamide diethanolamine 1.00 Sodium chlorine 0.15 Fragrance 0.40

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)