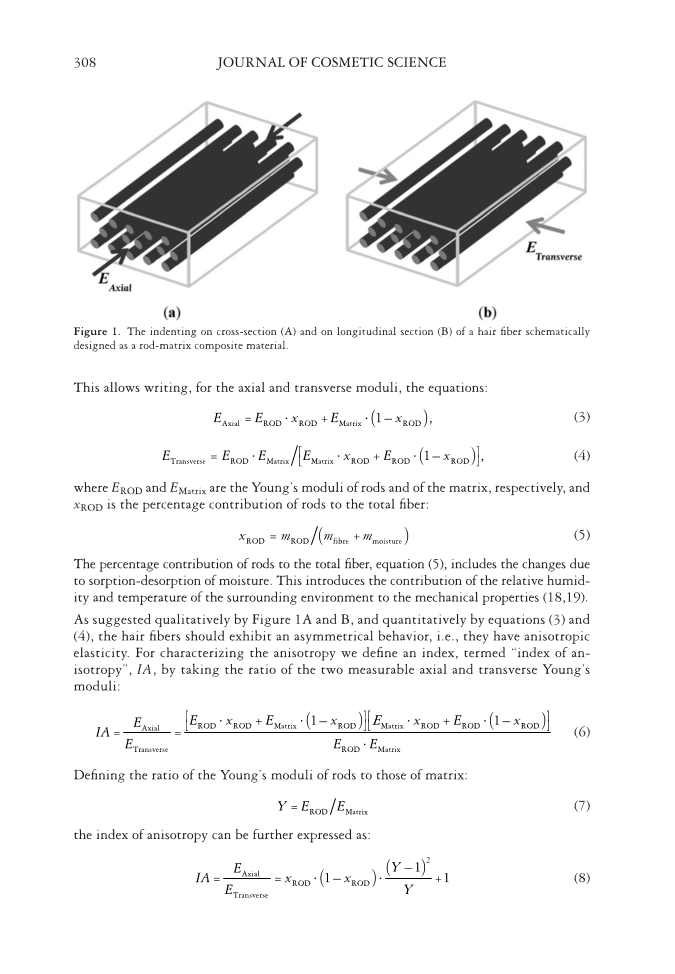

JOURNAL OF COSMETIC SCIENCE 308 This allows writing, for the axial and transverse moduli, the equations: ¸ ¸ Axial ROD ROD Matrix ROD = + 1– , E E x E x (3) ¯ ¸ ¸ ¸ ¢ ± Transverse ROD Matrix Matrix ROD ROD ROD = + 1– , E E E E x E x (4) where EROD and EMatrix are the Young’s moduli of rods and of the matrix, respectively, and xROD is the percentage contribution of rods to the total fi ber: ROD ROD fibre moisture = + x m m m (5) The percentage con tribution of rods to the total fi ber, equation (5), includes the changes due to sorption-desorption of moisture. This introduces the contribution of the relative humid- ity and temperature of the surrounding environment to the mechanical properties (18,19). As suggested qualitatively by Figure 1A and B, and quantitatively by equations (3) and (4), the hair fi bers should exhibit an asymmetrical behavior, i.e., they have anisotropic elasticity. For characterizing the anisotropy we defi ne an index, termed “index of an- isotropy”, IA, by taking the ratio of the two measurable axial and transverse Young’s moduli: ¯ ¯ ¢ ± ¸ ¸ ¸ ¸ ¸ ¢ ± ROD ROD Matrix ROD Matrix ROD ROD ROD Axial Transverse ROD Matrix + 1– + 1– = = E E x E x x E x E IA E E E (6) Defi ning the ratio of the Young’s moduli of rods to those of matrix: ROD Matrix = Y E E (7) the index of anisotr opy can be further expressed as: ¸ ¸ 2 Axial ROD ROD Transverse –1 = = 1– +1 Y E IA x x E Y (8) Figure 1. The indenting on cross-section (A) and on longitudinal section (B) of a hair fi ber schematically designed as a rod-matrix composite material.

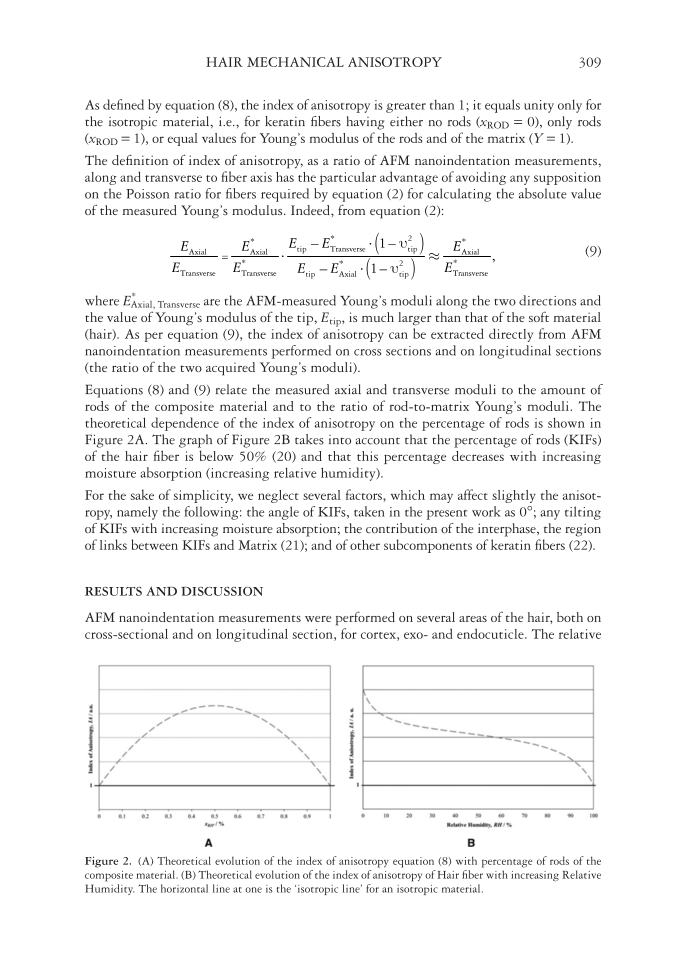

HAIR MECHANICAL ANISOTROPY 309 As defi ned by equatio n (8), the index of anisotropy is greater than 1 it equals unity only for the isotropic material, i.e., for keratin fi bers having either no rods (xROD = 0), only rods (xROD = 1), or equal values for Young’s modulus of the rods and of the matrix (Y = 1). The defi nition of index of anisotropy, as a ratio of AFM nanoindentation measurements, along and transverse to fi ber axis has the particular advantage of avoiding any supposition on the Poisson ratio for fi bers required by equation (2) for calculating the absolute value of the measured Young’s modulus. Indeed, from equation (2): ¸ V2 ¸ x ¸ V2 * * tip Transverse tip Axial Axial * * Transverse Transverse Transverse tip Axial tip – 1– = , – 1– E E* E E EAxial E E E* E E (9) where EAxial, * Transve rse are the AFM-measured Young’s moduli along the two directions and the value of Young’s modulus of the tip, Etip, is much larger than that of the soft material (hair). As per equation (9), the index of anisotropy can be extracted directly from AFM nanoindentation measurements performed on cross sections and on longitudinal sections (the ratio of the two acquired Young’s moduli). Equations (8) and (9) relate the measured axial and transverse moduli to the amount of rods of the composite material and to the ratio of rod-to-matrix Young’s moduli. The theoretical dependence of the index of anisotropy on the percentage of rods is shown in Figure 2A. The graph of Figure 2B takes into account that the percentage of rods (KIFs) of the hair fi ber is below 50% (20) and that this percentage decreases with increasing moisture absorption (increasing relative humidity). For the sake of simplicity, we neglect several factors, which may affect slightly the anisot- ropy, namely the following: the angle of KIFs, taken in the present work as 0° any tilting of KIFs with increasing moisture absorption the contribution of the interphase, the region of links between KIFs and Matrix (21) and of other subcomponents of keratin fi bers (22). RESULTS AND DISCUSSION AFM nanoindentation measurements were performed on several areas of the hair, both on cross-sectional and on longitudinal section, for cortex, exo- and endocuticle. The relative Figure 2. (A) Theoretical evolution of the index of anisotropy equation (8) with percentage of rods of the composite material. (B) Theoretical evolution of the index of anisotropy of Hair fi ber with increasing Relative Humidity. The horizontal line at one is the ‘isotropic line’ for an isotropic material.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)