600 Address all correspondence to Jennifer Marsh, marsh.jm@pg.com Fatigue Strength of Panelist Hair and Correlation With Hair Damage Measures JENNIFER M. MARSH, TIM J. FELTS, SHANE WHITAKER, CHRIS COWANS, AMANDA RITTER, TIAN CHEN AND HUSEN KANG The Procter & Gamble Company, Mason, Ohio, USA (J.M.M., T.J.F., S.W., C.C., A.R.) Procter & Gamble International Operation SA, Singapore (T.C., H.K.) Accepted for publication September 14, 2021. Synopsis The objective of this work was to investigate fatigue strength differences between root and tip hair for 41 Caucasian and 12 Asian panelists and correlate fatigue strength data to other measures of hair damage. In most cases both fatigue α- and β-values significantly decreased at tips, indicating a higher likelihood of fiber breakage and premature failure as hair became more damaged. This decrease in tip fatigue strength correlated positively with panelist coloring frequency for Caucasian panelists. In addition, a correlation was found between fatigue cycles to break (α-value) and oxidative damage (R2= 0.73), as measured by Fourier Transform Infrared Spectroscopy, and with cuticle integrity as measured by a scanning electron microscopy damage score (R2 = 0.77). An increase in oxidative and cuticle damage correlated with a lower α-value (i.e., lower cycles to break). The fatigue α-values were also compared with internal lipid levels including fatty acids, cholesterols, and wax esters as measured by gas chromatography–mass spectrometry. For root hair, there was a reasonable correlation (R2 = 0.36) between internal lipid levels and fatigue strength, but no correlation was seen for tip hair. For Asian panelists, a decrease in fatigue strength was also found with increasing oxidative damage, especially for those using powder bleaches. Both panelist groups had high person-to-person variability and no clear difference between Caucasian and Asian panelists. INTRODUCTION Hair strength and breakage is a critical area of research for the cosmetics industry because consumers regard “strong hair” as a desirable attribute. Hair strength assessments include the number of broken fibers shown when brushing and in the bathroom and broken hairs/ split ends still on their head. The cosmetics industry has developed multiple methods to measure hair strength: measuring the inherent mechanical properties of single fibers (1) and mimicking the combing/brushing process (2). The focus of this paper is on single-fiber fatigue mechanical properties and a comparison of fatigue strength measurements between different panelist samples and between root and tip. J. Cosmet. Sci., 72, 600–610 (November/December 2021)

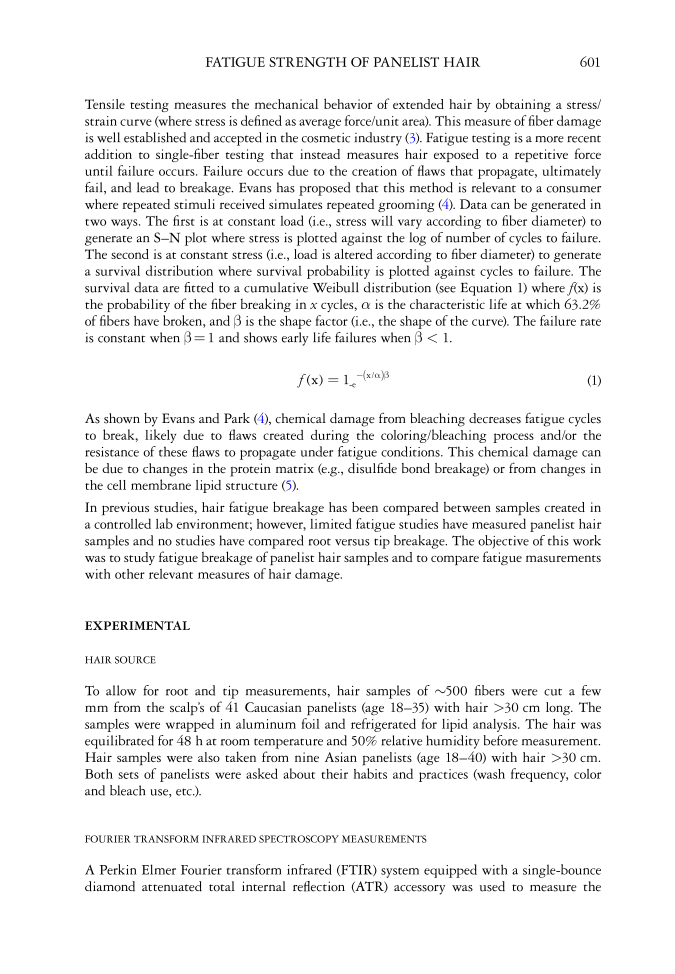

601 FATIGUE STRENGTH OF PANELIST HAIR Tensile testing measures the mechanical behavior of extended hair by obtaining a stress/ strain curve (where stress is defined as average force/unit area). This measure of fiber damage is well established and accepted in the cosmetic industry (3). Fatigue testing is a more recent addition to single-fiber testing that instead measures hair exposed to a repetitive force until failure occurs. Failure occurs due to the creation of flaws that propagate, ultimately fail, and lead to breakage. Evans has proposed that this method is relevant to a consumer where repeated stimuli received simulates repeated grooming (4). Data can be generated in two ways. The first is at constant load (i.e., stress will vary according to fiber diameter) to generate an S–N plot where stress is plotted against the log of number of cycles to failure. The second is at constant stress (i.e., load is altered according to fiber diameter) to generate a survival distribution where survival probability is plotted against cycles to failure. The survival data are fitted to a cumulative Weibull distribution (see Equation 1) where f(x) is the probability of the fiber breaking in x cycles, α is the characteristic life at which 63.2% of fibers have broken, and β is the shape factor (i.e., the shape of the curve). The failure rate is constant when β = 1 and shows early life failures when β 1. f ( x) -e x/α)β = ( 1 - (1) As shown by Evans and Park (4), chemical damage from bleaching decreases fatigue cycles to break, likely due to flaws created during the coloring/bleaching process and/or the resistance of these flaws to propagate under fatigue conditions. This chemical damage can be due to changes in the protein matrix (e.g., disulfide bond breakage) or from changes in the cell membrane lipid structure (5). In previous studies, hair fatigue breakage has been compared between samples created in a controlled lab environment however, limited fatigue studies have measured panelist hair samples and no studies have compared root versus tip breakage. The objective of this work was to study fatigue breakage of panelist hair samples and to compare fatigue masurements with other relevant measures of hair damage. EXPERIMENTAL HAIR SOURCE To allow for root and tip measurements, hair samples of ∼500 fibers were cut a few mm from the scalp’s of 41 Caucasian panelists (age 18–35) with hair 30 cm long. The samples were wrapped in aluminum foil and refrigerated for lipid analysis. The hair was equilibrated for 48 h at room temperature and 50% relative humidity before measurement. Hair samples were also taken from nine Asian panelists (age 18–40) with hair 30 cm. Both sets of panelists were asked about their habits and practices (wash frequency, color and bleach use, etc.). FOURIER TRANSFORM INFRARED SPECTROSCOPY MEASUREMENTS A Perkin Elmer Fourier transform infrared (FTIR) system equipped with a single-bounce diamond attenuated total internal reflection (ATR) accessory was used to measure the

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)