TECHNIQUES FOR ASSESSING RHEOLOGICAL PROPERTIES 449 The original Institute of Petroleum grease testing cone (9) comprised a small angle (30 ø) cone superimposed on a wide (90 ø) angie cone. With this type of cone the geometry of the system becomes complicated when the penetration depth exceeds the height of the 30 ø cone, and equations (V) and (VI) are no longer applicable. A smooth, single angle cone over- comes this fault (10). For long service it can be made of aluminium with a tip of hard steel. Investigations with cones of different angles (11) gave the following relationship where K2 is a constant. Reproducibility is most satisfactory when p is restricted to 7.5 - 20 mm. Haighton classifies materials according to S O by the general scheme shown in Table IV. Table IV Textural Classification of Materials according to Yield Value (lø) Yield value (gm/cm •) Assessment 50 50 - 100 100 - 200 200 - 800 800 - 1000 1000 - 1500 1500 Very soft to just pourable Very soft, not spreadable Soft, but already spreadable Plastic and spreadable Hard, but satisfactory spreadable Too hard, limit of spreadability Too hard The rod penetrometer consists of a metal rod surmounted by a small platform. The base of the rod is brought into contact with the surface of the sample, and the depth, or rate, of penetration determined for different loadings of the platform. If the load is converted into shearing stress, and penetration into velocity gradient, then, in the case of non-Newtonian flow, a curve will be obtained corresponding to that for pseudoplastic or plastic flow as shown in Fig. 2. A similar type of curve is obtained with the cone penetrometer using cones of different weights. Pseudoplastic flow can often be defined by 1 V -- S n (VIII) where n is a constant.

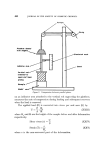

45O JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS If a yield value is observed equation (VIII) becomes (12) 1 v (s- So) n (IX) Equation (IX) reduces to Bingham's equation for plastic flow when n = 1. in all other cases • * is not the same as the true viscosity •q, nor does it have the dimensions of viscosity. When n • 1, the sample is said to exhibit "quasiflow." Many criticisms have been levelled against equations (VIii) and (IX) since they can be made to fit most curves by suitably adjusting the values of the constants. Furthermore, when S changes, n sometimes alters • * may also be affected. COHESION Interest in the stickiness, or tackiness, of materials led to the design of an instrument to measure the force required to pull a movable plate away from a stationary plate when a thin layer of sample is sandwiched between them (13,14). This principle has proved useful for measuring the increase in tackiness which occurs when lotions and ointments dry after rubbing into the skin (15). Two kinds of forces are involved in these measurements, viz. cohesion between the individual particles, and adhesion between the sample and plates. When cohesion exceeds adhesion, rupture occurs at the surface of the sample in contact with the movable plate, thus providing a measure of stickiness. Alternatively, if adhesion exceeds cohesion, rupture occurs within the sample itself, and one derives a measure of the internalstrength. Some materials show decreasing stickiness with increasing stiffness. Their consistency can be examined with an instrument (16) of the basic design shown in Fig. 4•. The sample is deposited in a Petri dish and the surface is carefully levelled and smoothed out. A circular steel plate of smaller diameter than the dish, which is connected by a vertical rod to two cords via metal rod junctions and an Oldak gauge, is brought carefully into contact with the upper surface of the sample. The upper cord is attached to an axle which applies an upward force to the steel plate when rotated by a constant speed motor. This force causes a metal plate, which passes through the lower metal rod junction, to bend in the centre since it is fixed towards its extremities over two knife edges. The deformation is recorded by the gauge. The maximum reading recorded, viz. when the upward acting force just exceeds the cohesion, is related to the strength of the material.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)