TECHNIQUES FOR ASSESSING RHEOLOGICAL PROPERTIES 455 F *- 2A (Xm) where F (= mg) is the load placed in pan W, and A is the cross-sectional area of S• and S•. The creep compliance curve (Fig. 6) can be sub-divided into three distinct regions. {1) A region of instantaneous elastic compliance (A - B) with a modulus E o, in which bonds are stretched elastically. If shear does not continue beyond this point, recovery is complete when stress is removed. The instantaneous elastic compliance is given by 1 Ja(t) Co -- -- (XIV) E o where Ja is the instantaneous elastic deformation. (b) A region of retarded elastic compliance (B - C) with an elastic modulus E R, viscosity %, and retarda tiontime ,• (---- •/E•), in which bonds break and reform. Actually, bonds do not all break and reform at the same rate so that all three parameters should be replaced by spectra showing a wider distribution of values. Present discussion will be restricted to the simplest model. CR _ 1 _ C(1- e-t/-rR) •- Jb(t) (XV) E R where Jb is the retarded elastic deformation, and C R represents an average of all the compliances involved. (c) A region of Newtonian flow (C - D) with viscosity •ls. Once the bonds have ruptured, i.e the time for them to reform is longer than the test period, individual particles or units flow past one another. Newtonian flow is proportional to the time of loading, so that Cs _ t _ Jo(t) (XVI) where Jo is deformation in the Newtonian region. Thus, the slope of the linear part of the curve is equal to 1[• s. The overall compliance for the whole creep curve is, therefore, J(t) _ Co + CR + CN = Co + C(1- e-%R) +t (XVII) Where t --• 0 J(t) -- C o (XVIII) Since C o and •ls are now known C• can be calculated from equation (XVII).

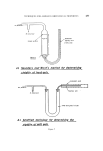

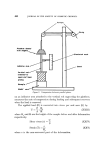

456 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS Equation (XVII) can be written in the form -t_ -t _ln IJ(t)_Co_C_t ) (XlX) -- '•'R CRTJR O' If the right-hand side of equation (XIX) is plotted against t, the slope of the line represents- 1/C R • R, so that •R and zR can be calculated since CR is known. In this way all parameters associated with the near-stationary structure of a solid material, and the effect of recipe modifications, processing, etc., can be studied. This technique has proved suitable for investigating soap texture. MODULUS OF RIGIDITY The main advantage of this test (20) for materials showing a high degree of elasticity is simplicity of the apparatus required. It consists of a glass capillary U-tube, one arm of which opens up into a wider bore tube, while the other capillary arm is graduated in mm (Fig. 7a). The tube is filled with mercury to the base of the wide-bore tube, and a fixed volume of sample is then introduced into the latter. In the case of a gel 20 ml of the warm solution is pipetted through the opening of the wide bore arm, and allowed to set overnight under careful temperature control. The sample is subjected to variable shear conditions by using air pressure, and the resultant displacements cause the mercury to move up the graduated capillary arm. Air pressures are registered with a mercury manometer. Provided L is very much larger than R pR 4 Ci ---- 8LB•H maximum strain at the tube wall maximum stress (xx) 4Q (xxI) r•R a PR (xxn) 2L where G is modulus of rigidity, P is the net applied pressure, i.e. corrected for the back pressure of mercury, L and R are the length and radius respectively of the cylindrical column of sample, B is radius of the capillary tube along which the mercury moves, H is displacement of the mercury meniscus, and Q is the volume displaced. The above apparatus is suitable for measuring high values of G.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)