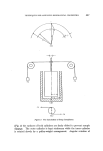

TECHNIQUES FOR ASSESSING RHEOLOGICAL PROPERTIES 457 cop/llory orro Sounders and Word's method for determining_ r._/gidity of hard gels. •0 mortomelet •l'i i,.•.' i i i '. ,'. ', I • Cop// Ior y Wide bore gloss 't/' tube Modified technique for determining. the r__/g/d/ty of soft gels. Figure 7

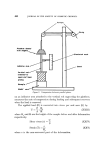

458 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS G should be measured over a wide range of strains since it may be influenced by strain in the same way as gelatin gels. For softer gels with much lower values of G, and where the deformations under stress may not be all elastic, a modified technique can be used (21). In this case the whole U-tube consists of wide bore glass (---1.5 cm dia- meter), and the arm to which pressure is not applied is attached to a nearly horizontal capillary (Fig. 7b) containing a drop of coloured alcohol. Move- ment of the alcohol along the capillary is proportional to displacement of gel in the U-tube under different air pressures. This procedure has proved suitable for rheological measurements on a hair dressing with "a distinct bounce due to its high degree of viscoelasticity," and other cosmetic products (15). When using either apparatus one must ensure that movement of indicator fluid results only from sample deformation, and not from sample slippage along the walls of the tube. The tensile strength of gels, and materials of similar consistency, can be estimated by extruding from a variable pressure viscometer fitted with a nozzle of 2-14 mm, and determining the quantity falling off under its own weight (22). Tensile strength is given by the ratio sample weight extruded/nozzle area. For thixotropic gels tensile strength is related to the time dependence of viscosity. Recently (23) a correlation has been observed between palate assess- ment of gum solutions and their rheological properties. Gums which feel very slimy in the mouth are usually only slightly non-Newtonian. As non-Newtonian behaviour becomes more developed the degree of sliminess decreases. SECTILOMETER The consistency of solid materials can be determined with this instru- ment (24). A fine wire held taut in a metal frame constitutes the cutting device (Fig. 8). A sample of standard dimensions is placed on a support platform, and its surface is brought into contact with the wire. By mechanically moving the platform upward at a very slow, steady, rate (e.g. 0.07 cm/sec), the wire cuts through the sample. The thrust on the wire is transmitted by the metal frame to a lever balance, where it is registered. This technique is not suitable for very soft materials because the wire does not cut through the sample until a minimal thrust has been developed. For a sample width of 3 cm this may be as much as 40 g.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)