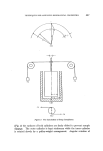

TECHNIQUES FOR ASSESSING RHEOLOGICAL PROPERTIES 441 used to examine more than one type of consistency. Some of these tech- niques which require the least complicated apparatus, and which find general use, will be described in some detail. VISCOMETERS Theory No force is required to bring about deformation of materials which show true fluid (Newtonian) flow. They have a constant viscosity irrespective of the applied force. Newtonian flow can be explained as follows. Let the space (x) between two parallel planes A (upper) and B (lower) be filled with fluid (Fig. 1). When a force F is applied to A it moves at a constant velocity (u) if B is stationary. As a result, all the liquid between A and B does not move with identical velocity instead the velocity varies from u in the layer adjoining A to 0 in the layer adjoining B. The rate of change in fluid velocity with distance from A, or rate of shear v, is given by du/dx. Shearing stress (S) is the force applied to unit area A. The viscosity of the liquid (•1) is given by S/v. Since v always changes to the same extent per unit change in S, it follows that •1 remains constant, and that it can be determined by a single measurement with any viscometer. *" V•loc/ty _-/u Figure I Model to illustrate NewtonJan Flow Many suspensions, emulsions, etc., show more complex (non-Newtonian) behaviour. In some cases the increase in v grows progressively larger per unit increase in S, up to a limiting value of S, so that •1 decreases. Above the critical value of S the ratio S/v, and therefore •1, remains constant.

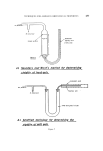

442 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS This type of behaviour is exhibited when structure is broken down during shear. Materials within this category which flow as soon as stress is applied are called pseudoplastics, whereas those requiring a minimum shearing stress (So) to establish flow are called plastics (Fig. 2). 5htari•g strtJ, ($) t•l.•tic flow Pl•udoplo#tic flow Al•wtonf•n flow Dflot.•t flow without Figure oe Types of flow behaviour In dilatant flow v decreases as S increases, so that • increases. This behaviour represents the reverse of pseudoplastic flow if there is no yield value, and the reverse of plastic flow if a yield value is observed. Most powders and closely packed dispersions exhibit dilatancy when closely packed. When sheared the packing must become looser, i.e. there is an initial increase in volume, before the individual particles can move past one another (1). Two other stress values may be quoted when reporting plastic flow data (2). These are the extrapolated yield value, which is the intercept on the S axis obtained by extrapolating the linear portion of the S-v curve, and the upper yield value, which refers to the value of S at which linear flow is first established (Fig. 2). Pure fluids never show a true yield value. It is often found in con- centrated dispersions of liquid droplets, or solid particles, in fluid media. To establish that a yield value actually exists it is necessary to establish

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)