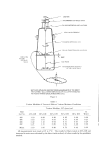

STABILITY OF SOME SPECIFIC EMULSIONS 593 ß • i•o. ß ' • ..,.$.• .. ,. • •.• . '- • ..' ,• • ' •'• 9 .• c?:' ¾'• ,4.•,,*•' g.-• •.' :7 -' • ß ,, . ... •. •' .. •, ), •' •, ?• . . Figure 1. Water-in-oil cream emulsion, freshly made. Polarized light, 165X .•..•: • •.•...• '•"' '' • • ' '" :--• .. .$.• ....... ß •{..:• :• ,•'.• . •' -' . •. '/•' .::. %' 4' Figure 2. Water-in-oil emulsion, one year old. Polarized light, 165X Figure 3. Water-in-oil emulsion, one year old. Left half: Votator-processcd cream right half: traditionally pro- cessed (see text). Polarized light, 165X -• --•, • :' . .... • .::• .. .... Figure 4. Oil-in-water antiperspirant cream, freshly made. Polarized light, 165 X - '": ' .•' •'.. ' .. ,' .,,t.• .' "•/-. - ' ' ß .. .:: •.. : .- :.:.. . ?:...'. ".'.' !i :--:.L. ': -.. :•_•..:.....- •.•..• -:-.:: ,..-.:. :-.?• .:..: . ".. - • -..:•.....:• •. :..?. :.. •:.'. • . ..:.-.:...• .:•.", ... --:: ß .. . ':2:.::,7"-,. ':. :.:.•:..:':.y-/:... ". .... '7:: '"' /• -' •:'•-•..-...,-..7% '' ...... :.'.• ',•-. .,... ß , ..... .......:.-..:: •.. :• .,.- .. *•:'•- ,,.• .... • /... .......--.... '. . • ,. '-.. . ....... .•.:..•,,. ß - / ..-•' ..: ... -?. •:•.• . -. •'• ,, - ,•,. ,*. -.::. - -•:•. • •,.....• • ½ . •. ½• , '•.' • ß .•.• • ß i •,• ' Figure 5. Oil-in-water antiperspirant cream, two weeks old. Polarized light, 165X .::.• • ..... •½ .,.' •. : ::..:• ...• .: :. i Y:L'". ß • ........,• . .... - : ....... , .:•. ..... ... :• •..... .... .'t• ' "'"" '""J' •.• 2'•. .g •"'• ... .• •."½. :.•. ß ß ......, •. 7 .... - . . . ... Figure 6 Oil-in-water antiptrspirant cream, three months old. Polarized light, 165X

594 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS regular particle sizes superimposed on a rather uniform basic emulsion should be noted. Figure 2 shows the material after about one year of storage, although this condition does not change significantly after the first 3-4 months' storage. Growth of the solid agglomerates, especially the large cluster in the top center of the figure, is observed. It was eventually noted that variability in granule size was related to the length of the cooling period after milling. Also, the granules were crystalline and attained their maximum growth in a few months. Their composition by infrared spectrophotometric analysis roughly approxi- mated beeswax. It was also found that the cream did not become grainy on long-term storage if microscopic examination, one week after manu- facture, did not reveal clumps over about 10-20 • in diameter. Based on these facts, rapid cooling was employed to reduce the size of the crystalline particles. Cooling was accomplished by use of the Chem- etron Votator ©* with the results shown in Fig. 3. This is a split photo- micrograph: the right half shows an extreme example of a cream made by the original method, the agglomerates having grown to the size of palpable grains the other half shows a Votator-processed batch which reflects this improved microscopic appearance in its good macroscopic quality. Both creams were over one year old when photographed. Guessing at the underlying process, one might suggest that the bees- wax, in addition to functioning at the interface of oil and water as a soap- type emulsifier, stabilized the emulsion by increasing the viscosity of the continuous phase. However, due to its limited solubility a portion crystallized out during the cooling process. If the cooling is slow enough, a smaller number of crystals form, the larger ones growing at the expense of the small ones. Under the influence of sudden cooling, a large number of small seeds crystallize out, and under conditions of low mobility and limited residual insoluble matehal, there is limited growth of the original crystals. This may be analogous to crystallization techniques in old wet-method inor- ganic analysis or in purification of organic materials by crystallization. A ntiperspirant Cream The second case concerns a somewhat similar situation involving an oil-in-water antiperspirant cream. The primary system was a combina- tion of nonionic emulsifiers with a high HLB number using glyceryl monostearate (GMS) as stabilizer and thickener. The cream was pro- cessed in a routine manner without homogenization. * Votator Division, Chemetron Corp., 2820 West Broadway, Louisville, Ky.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)