TORSIONAL PROPERTIES OF HAIR Figure 2. Photograph of a hair style produced by setting the waved hair in the front hair line on rollers with water and dry- ing. The detail illustrates the helical arrangement of the style. 577 larity can often be observed by wetting out single fibers of naturally wavy hair and floating them freely on the surface of water in a large container. A similar situation is obtained when one looks at hair just after removal of setting or styling rollers, or after the hair tresses have been set into pin curls and combed out. Here, also, one typically finds the helical coil arrangements, as shown in Fig. 2. These photographs illustrate the tendency to coil formation of hair tresses in setting, as in certain style configurations desired by some consumers. This evidence permits us to assert, therefore, that in several of the very common operations women employ in dealing with their hair it is usual to find the fibers arranged in the form of helices. It is now pro- posed to discuss the behavior of typical helical tresses by examining the characteristics of a mechanical spring for which a good deal of the theory has been developed. _A_ MECHANICAL SPRING MODEL AND FIBER TORSION Classical physics has treated the mechanical behavior of springs (1, 2). The deflection or extension of a helical spring coil under axial loading is generally given by the following equation: KPrSn A = Gd • (1)

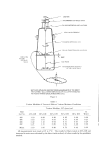

578 where: JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS K PJ..½ rm //•= G •L 4- t r'- 'j'" A = DEFLECTION UNDER LOAD P K = CONSTANT ,• = RAglLJS OF COIL •r• = qUMBE,ø,OF'F'JR':qS G = SHEAR MODULUS • -- DIA.'4ETER OF .SPRING •1R •'. A MECHANICAL SPRING MODEL SHOWING THE VARIABLES INVOLVED IN THE EXT•N$10N OF A COIL UNDER LOAD. Figure 3 A = deflection K = proportionality constant P = axial load r = radius of the spring n = number o[ coils G = shear or torsional modulus d = diameter of the wire composing the spring The sketch shown in Fig. $ illustrates the key variables. It is important to emphasize the conditions under which this theoretical relationship holds: The spring is one of large spring index, i.e., the diameter of the spring is large compared with the diameter of the wire of which the spring is made the deflection or extension under load is assumed to be small the pitch angle is small, i.e., the spring is relatively flat and the spring matedhal exhibits completely elastic behavior, i.e., no creep takes

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)