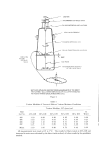

TORSIONAL PROPERTIES OF HAIR 581 successive swings in a torsion pendulum experiment this will result in large values of S, the logarithmic decrement. Measurement of S is relatively simple. Torsion bobs were made of discs of sheet metal with a highly reflective chrome-plated surface. A light beam focused on the torsion bob through the glass jar placed centrally with respect to a semicircular scale about 60 cm away (Fig. 4). Reading of the light spot on the scale was simple and determined the amplitude of any oscillation. In practice, the amplitude of the first and tenth swing was determined for the calculation of S and the time period (T) for the ten swings measured with a stopwatch for the calcula- tion of G. It was also desired to measure fiber properties in torsion in the wet state, as is frequently done in fiber tensile measurements. The pen- dulum method is not suitable for wet testing accordingly, a new pro- cedure was selected--the direct twist method, based on the principles of a technique described by Morton and Permanyer (7). In brief, the method used consists in mounting a test fiber in series with a reference wire made of an elastic substance such as steel, quartz, or tungsten, the last being employed in the present case. As shown in Fig. 5, the fiber is prevented from rotating at the bottom, while twist can be inserted into the wire at the top with a slow speed motor rotating at 1-4 rpm as desired. An indicating pointer is present on the lightweight piece connecting the wire and fiber. In operation, switching the motor on inserts twist into the wire-fiber assembly, the total twist being noted on the counter attached to the motor. The pointer at the bottom of the wire (the top of the fiber) is followed and represents the twist in the fiber. By difference, the twist in the wire is obtained since the wire is elastic, the twist in it corresponds to a known shear stress which is the same in the reference wire and in the fiber being tested. The stress may be com- puted using the constants from the literature or from measurements of torsion modulus of the wire made by an independent (pendulum) method. The fiber may be equilibrated at any given atmosphere or may be im- mersed in water or any other liquid during the measurement. Results of measurement of fibers exposed to a wide range of moisture conditions are shown in Table I. Reported is the torsional stiffness of replicate fibers from four different samples of authentic hair in the un- waved state. Most striking is the response of the fibers to moisture. As the humidity increases the value of the torsional modulus decreases substantially. The observed effect of moisture is considerably larger than in the case of tensile measurements: the tensile modulus decreases by only a factor of two in going from 65% RH to water wet fibers.

COUNTER SYNCHRONOUS SLOW SPEED MOTOR PIN VISE SUPPORTING WIRE ANO FLEER i3ELL JAR (SJPPORTED) fU•GSTEN REFERENCE INDICA FI:•G PIN AND CIRC'JLAR oeCALE CJLLAR CON:tECTI IG 'WIRE A:4J 713,• TEST YOKE PREVENTING ROTAI-IU:i OF T tE E,4D OF FltlrZR SKETCH OF APPARATUS USED FOR TORSION MEASUREMENTS BY THE DIRECT TWIST METHOD. SMALL SKETCH SHOWS DETAIL OF COLLARNITltlNglCATI IG PIN PASSING THROUGH CIRCULAR-MEASURING SCALE. Figure Table I Torsion Modulus of Unwaved Hair at Various Moisture Conditions Torsion Modulus, 10 m dynes/cm 2 Hair In Lot No. 41% RH 58• RH 65% RH 81% RH g3• RH Water 405 1 . 13 O. 98 O. 83 O. 65 O. 39 O. 20 404 1.13 1.01 0.91 0.71 0.45 0.21 403 1.22 1 . 12 O, 94 O. 77 O. 47 O. 24 402 1.27 1,11 O. 89 O. 79 O. 38 O. 22 Mean 1.19 1.06 O, 89 O, 73 O. 42 O. 22 All measurements were made at 21 4- iøC. The results for fibers tested at 65•0 RH and immersed in water were obtained by the direct twist method, all other results by the pendulum method.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)