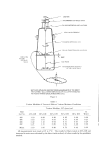

TORSIONAL PROPERTIES OF HAIR 583 Hair Lot No. Table I I Creep Properties of Unwaved Hair under Torsion at Various Moisture Conditions __ _ Creep in 5 Minutes at a Constant Couple of 3.1 dyne-era, Turns per cm Length a Logarithmic Decrement In 41% RH 58% RH 81% RH 93% RH 65% RH Water 405 O. 13 O. 13 0.19 O. 26 O. O1 O. 08 404 O. 12 O. 13 O. 16 O. 22 O. O1 0.08 403 O. 11 0.12 O. 17 0.24 0.01 0.08 402 O. 13 O. 14 0.21 0.29 0.01 0.08 Mean O. 12 O. 13 O. 18 O. 25 O. O1 O. 08 All measurements were made at 21 4- 1 øC. The results for fibers tested at 65% RH and immersed in water (creep) were obtained by the direct twist method, all other results (logarith- mic decrement) by the pendulum method. a A couple of 3.1 dyne-cm produces a fiber twist in a typical hair of about 0.5 turn per cm at 65% RH and about 3-4 turns per cm in a wet fiber. The data for the individual hair lots do not differ greatly no morpho- logical or chemical basis for the observed small differences could be found. The creep behavior of unwaved hair is reported in Table II in terms of the fiber flow parameters obtained from the two torsion methods em- ployed. Again, the plasticizing effect of moisture is noted. The logarithmic decrement as measured in the pendulum method increases sharply in going from 41 to 93% RH, and the creep measured directly is greater by almost an order of magnitude in going from 65% RH to water-immersion conditions. In examining the data in Tables I and II, it is easy to see why wet hair is easier to set than dry, why it conforms well to the imposed con- figuration in the wet state and why it holds this configuration on drying. Wetting the hair reduces the stiffness greatly, so that it may readily be wrapped around a styling rod or the finger for pin curling. Being held in the wrapped form, the induced torsional stress decays rather quickly, and on drying the set is "frozen" in. The dry fiber is restored to its initial physical state of relatively high stiffness. The tendency for creep is also comparatively low in the dry fiber, and so long as the ambient humidity remains low the set configuration resists deformation. The effect of a typical permanent waving treatment is seen in the data of Table III. The torsion moduli are similar to those in Table I in

584 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS Table III Torsion Modulus of Waved Hair a at Various Moisture Conditions Torsion Modulus, 10 •ø dynes/cm • Hair In Lot No. 41% RH 58% RH 65% RH 81% RH 93% RH Water 405 1.16 1.05 0.96 0.68 0.37 0.14 404 1.27 1.13 1.09 0.80 0.44 0.17 403 1.34 1.23 0.99 0.81 0.39 0.12 402 1.24 1.11 0.91 0.76 0.40 0.13 Mean 1.25 1.13 0.99 0.76 0.40 0.14 All measurements were made at 21 :k IøC. The results for fibers tested at 65% RH and immersed in water were obtained by the direct twist method, all other results by the pendulum method. • Permanent waving process corresponded to standard type of commercial treatment except that process time was extended to 90 minutes. Table IV Creep Properties of Waved Hair •* under Torsion at Various Moisture Conditions Creep in 5 Minutes at a Constant Couple of 3.1 dyne-cm, Turns per cm Length b Hair Lot No. 65% RH In Water 405 0.01 0.10 404 0.01 0.10 403 0.01 0.12 402 0.01 0.09 Mean 0.01 0.10 All measurements were made at 21 :k 1 øC. The results for fibers tested at 65% RH and immersed in water (creep) were obtained by the direct twist method. • Permanent waving process corresponded to standard type of commercial treatment except that process time was extended to 90 minutes. b A couple of 3.1 dyne-cm produces a fiber twist in a typical hair of about 0.5 turn per cm at 65% RH and about 3-4 turns per cm in a wet fiber. that moisture acts to decrease them. Most interesting, however, is the finding that waved hair on the average tends to exhibit greater stiffness at low humidities. The effect of permanent waving in increasing the torsional stiffness is seen in most, but not all, samples hair lot 402 is an example of a case in which the permanent waving treatment produced no significant alteration in the "dry" torsional properties. The damping capacities of the hair given by the logarithmic decre- ment are, within experimental error, similar in the waved and unwaved fibers and are not reported here. The creep properties of the waved

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)