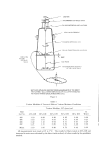

STABiLITV OF SOME SPECIFIC EMULSIONS 597 stabilization occurs by gelation of the interface by GMS. If disturbed after this initial setting period, the interfacial film is less structured, al- lowing migration of dispersed GMS into the continuous phase at an ac- celerated rate with subsequent loss of the stabilizing effect of the gelled structure. A ntiperspirant Lotion The third example is an antiperspirant emulsion. This one is a rather viscous oil-in-water lotion. The viscosity builder and stabilizer con- sisted mainly of cetyl alcohol and a purified, high-melting glyceryl monostearate. The product was made in a Gifford-Wood Agi-Mixer.* Figure 10 shows the appearance of the freshly prepared bulk and Fig. 11 the S-day old packaged material. The viscosity at this point is about 3000 cps. It ig quite apparent that crystal growth is already consider- ably advanced. Figure 12 depicts a batch that is one year old. The large clumps or "rosettes," mainly disintegrated by now, appear to be GMS, and the rods may be cetyl alcohol. At this point the emulsion tends to separate slightly, and the viscosity has dropped to less than 500 cps. Attempts to improve this formula by process changes did not appear likely to succeed or to be economical. It did seem logical to attempt to retain the valuable viscosity-building characteristics of GMS and cetyl alcohol while impeding their tendency to crystallize. This was attempted through use of a lower-melting, less crystalline GMS, made from a "triple-pressed" stearie acid, and inclusion of other materials in the oil phase to act as plasticizers or improve solvency. Figures 13 through 15 illustrate the results. Figure 13 shows the fresh bulk product with an average particle size of about 10-13 u. After one month, some glyeeryl monostearate rosette formation has occurred, as shown in Fig. 14, but growth is slow, viscosity stationary, and prognosis for shelf life appears to be good. Figure 15, a photomierograph taken after six months, confirms the anticipated stability. The macroscopic stability, with respect to viscosity and visual characteristics, is also satisfactory. CONCLUDING COMMENTS In the foregoing examples, considerable additional information con- cerning stability tests, viscosity measurement, and analytical data were collected but were omitted from this report in the interest of clarity. * Gifford-Wood Co., Hudson, N.Y. 12534.

598 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS However, these data were helpful in analyzing the problems and arriving at solutions. The points of importance are that solubility and crystallization char- acteristics of the viscosity builders and stabilizers were predominantly in- fluential in the long-range stability of the product. Where these char- acteristics offered problems, they were amenable to correction by process changes or modification by other agents in a logical manner. It should also be noted that photomicrography was particularly help- ful in clarifying the process of stability breakdown and predicting the eventual fate of the emulsion. ACKNOWLEDGMENT Thanks are due to Joseph Miglietta for the preparation of the photo- micrographs used in this work. (Received November 1, 1966) REFERENCE (1) Sherman, P., A method for predicting rheological changes in emulsion products when aged, J. Soc. Cosmetic Chemists, 16, 591-606 (1965).

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)