j. Soc. Cosmet. Chem., 41, 379-390 (November/December 1990) Characterization of surface deposits on human hair fibers H.-D. WEIGMANN, Y. K. KAMATH, S. B. RUETSCH, P. BUSCH, and H. TESMANN, TRI/Princeton, P.O. Box 625, Princeton, NJ 08542 (H.-D, W., Y.K.K., S.B.R.), and Henkel KGaA, Di•)seldorf-Holthausen, Federal Republic of Germany (P. B., H.T.). Received September 7, 1990. Presented in part at the 8th International Wool Textile Research Conj•rence, Christchurch, New Zealand, February 7-14, 1990. Synopsis The deposition, substantivity, and buildup of various formulations on the surface of untreated and oxidized hair fibers have been investigated using a combination of wettability scanning and microfluorometry. Wettability scanning along the length of the fiber establishes variations in surface energy and thus can explore only increases in surface coverage as a result of multiple treatments. On the other hand, microfluoro- metry, which involves incorporation of appropriate fluorochromes into the formulation, can provide infor- mation about the thickness of surface deposits and thus can be used to study buildup phenomena during multiple applications. Multiple treatments with a formulation containing a cationic polymer in conjunc- tion with an anionic ethersulfate surfactant lead to buildup of surface deposits during multiple treatments. These deposits are strongly held even on unoxidized hair fibers, and repeated rinsing does not completely remove them. In contrast, a formulation containing keratin hydrolysate deposits on the scale faces of the hair surface, with no buildup in multiple applications. Deposition of this material on unoxidized fibers results in an increase in hydrophilicity of the fiber surface that appears to increase slightly with multiple treatments, possibly reflecting more uniform distribution on the surface. INTRODUCTION Deposition of compounds on human hair fiber surfaces is used extensively to modify appearance, manageability, and grooming style. Knowledge of the extent and nature of the deposition is critical for the development of appropriate hair care formulations, since excessive buildup of such materials can have detrimental effects on the behavior and esthestics of the hair assembly. TRI has developed methodologies that permit rapid assessment of the distribution and thickness of surface deposits on fibrous materials. The use of liquid membrane wettability scanning, based on surface energy changes produced by a treatment, provides a profile of surface coverage along the length of a hair fiber (1). Microfluorometry, on the other hand, which relies on the incorporation of fluorochrome tracers into the formulation, is able to assess the relative thickness of surface coatings. Fluorescent tracers have been used extensively in qualitative character- ization of surface deposits on wool fibers (2-4) and also on hair (5). The introduction of microfluorometry with its ability to scan fluorescence intensity across a fiber or along its length has made it possible to quantify the distribution of surface deposits on fibers, at 379

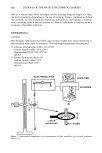

380 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS least on a relative basis. Both techniques involve scanning along the length of a fiber, the level of resolution depending on the rate of scanning. Using a combination of these two methods, we have studied the deposition, substantivity, and buildup of formula- tions containing either a cationic polymer or a keratin hydrolysate in conjunction with an anionic ethersulfate surfactant. EXPERIMENTAL MATERIALS The European dark brown hair fibers used in these studies were rinsed extensively in demineralized water prior to treatment. The following formulations were prepared: 1) Cationic cellulose ether (CCE): 2% (0.5%) Sodium laureth sulfate: 14% (14%) Demineralized H20: 84% (85.5%) pH 6.3 2) Keratin hydrolysate (Ker): 5% Sodium laureth sutfate: 14% Demineralized H20: 81% pH 6.4 ELECTROBALANCE COMPUTER O/ RECORDER - o.+ MELM• BER I Figure 1. Experimental arrangement for the measurement of fiber wettability by the liquid membrane method (1).

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)