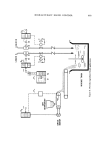

HIGH-ACCURACY BLEND CONTROL 601 quired to operate and monitor the system, thus releasing plant personnel for other tasks. Improved product quality is another benefit of digital blending systems which means increased profits for the user. The ability to consistently blend high grade products results in higher dollar return for essentially the same fixed costs. EXAMPLE APPLICATIONS Bulk Ingredient Blending Figure 6 illustrates the blending of fluorocarbon products at bulk termi- nals. This is a flow diagram of an installation where the outdated method of batch blending into weigh tanks has been replaced by a continuous operation which blends directly into a tank truck. A pressure control system on the manifold outlet maintains header pressure at required level. Two economic advantages have been of special significance to the users of digital in-line blending on this application. The most important is a savings in time. Previously, the user's problems caused by varying vapor pressures and wide ranges of densities made it extremely difficult to achieve an accept- able blend in less than two or three days. With in-line blending, most of these problems were erased, and average blend times have been reduced to approximately four hours. The second advantage, also important, is that the user is able to provide consistently high quality fluorocarbon products to his customers. Aerosol Product Canning Figure 7 depicts an installation of digital in-line blending directly into cans. Note the piston accumulator just upstream of the canning machine. This is used to accumulate enough surge capacity, ordinarily 5 to 10 gallons, to allow high enough flow rates to use turbine meters and also to provide the ma- chine with a continuous supply of blended propellant. High and low limit switches in the accumulator turn the blending system on and off as required to maintain the required capacity. Continuous on-spec product allows significant time savings in this system by eliminating the intermediate step of blending into batch tanks from which cans are filled. One user's production now exceeds 60,000 filled cans per 8- hour shift. In addition, the hazard of fire in blending highly flammable aero- sols is greatly reduced. Wet/Dry Ingredient Blend This application, although proven in many industries, may be somewhat hypothetical at the present time for cosmetics process .operations. The purpose

002 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS FLUOROCARBON FLUOROCARBON HYDROCARBON ()()( ) 02 P I STON ACCUMULATOR TO FILLING MACHINE 02 z D O• D• Figure 7. Blending application for aerosol product canning in presenting it here is to perhaps stimulate interest to apply digital blending to operations not previously considered for this kind of control. The diagram in Fig. 8 shows a digital blending system which is ratioing a dry material with two liquids into a blend. The dry material is carried to the system on a weigh belt feeder. A constant feed of material is loaded onto the feeder through a fixed gate. The measurement signal to the controller is developed by multiplying the weight of the material on the belt, as deter- mined by a load cell, by the speed of the motor driving the belt. This signal is then converted to a pulse signal and fed to the controller as the required volumetric pulse-type measurement signal. Pulse comparison is accomplished in the normal manner and the error signal, now instead of repositioning a control valve, is used to vary the speed of the belt. The rest of the system is the same as an all-liquid blending system. The basic economic advantage of combining wet and dry ingredients in this manner are the same as for straight liquid blends. In addition, the physi- cal handling of the dry ingredients is lcss difficult and the uncertainties of manual dumping are eliminated.

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)