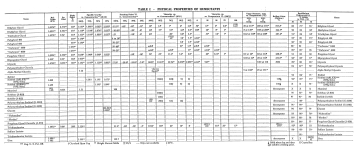

22 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS however, as the concentration of humectant is increased, the dif- ference in effectiveness becomes negligible. At 50% R.H. storage, all of the humectants provided protection with no appreciable dif- ferences apparent. This was also true at 70% R.H. The per cent weight loss data for the non-ionic type creams may be found plotted Figure 14.--Crust Measuring Balance Beam. The free swinging beam, pivoted about the left-hand pair of setscrews, applies force to the cream by means of the hollow cylinder (cork borer) hung from the right- hand pair of set screws. The long rod weight and hanging counterweight permits adjust- ment of the beam. rs. the concentration of humec- rant in the lower rows of Figs. 10 to 13. OCCURRENCE AND MEASUREMENT OF CRUST FORMATION It is our belief that some of the differences of moisture loss rate be- tween, and within, the two series of samples are related to the formation of a crust on the exposed stirface. On the soap-type creams the crust formed is sufficiently thick and dense so that it may be felt and measured. Humectants are added to prevent or retard "drying out" of a cos- roetic cream. This drying is usually accompanied by hardening of the cream, and at times by the forma- tion of a hard crust at the top sur- face of the cream. The problem, then, is twofold: first, to prevent or retard the loss of water during accidental exposure, and second, to preserve the texttire or consistency of the cream even though water is lost. We found that texture and consistency could not be correlated with loss of water alone. In fact, texttire and the t•rmation of a hard crust on loss of water are a function of the type of emulsifier used. Soap emulsified creams developed a crust in less than 24 hours' exposure and no measurable or apparent crust was formed in 48 hours when non- ionic emulsifiers were employed. To measure this crust formation, a compression balance was built that applies load at a constant rate of deformation. The compression balance (see Fig. 14) was designed

HYGROSCOPIC AGENTS AND THEIR USE IN COSMETICS 23 over a Scott Tester, using a pen- dulum weight that swings in an arc to apply the required force to the member that penetrates the cream. The jar of cream is placed on a plat- form that is raised at a steady, slow rate. The movement of the pene- trating member is slight so as to de- form the cream at a steady rate ac- cording to the advancement of the platform carrying the sample. Pre- liminary tests indicated the desira- bility of using a blade to penetrate the cream rather than a solid plunger, since when either a large or small plunger was used quantities of the sample were extruded from beneath the plunger as it was forced into the cream. A circular blade was finally adopted, a thin wall brass tube. Our results with this equipment agreed with appearance and feel of the creams. The creams, when subjected to the tester, produced loading curves of four general types as seen in Fig. 15. The type "A" curve un- doubt,edly results where no crust is present and the cream is of suffi- ciently low consistency so that the cream is immediately penetrated by the brass tube as it advances. As the consistency of the cream in- creases the slope of this curve in- creases. The type "B" curve also results where there is apparently no crust however, for the most part, the type "B" curves obtained showed a definite change of slope as the creams continued to be pene- trated, apparently indicating a heavy consistency. The type "C" curve is produced by a cream that possesses a hard, thin crust. A large force is required to break through the crust, but when this has been penetrated, the inertia carries the brass tube down into the cream a distance depending on the consistency at which point the curve rises slightly or levels off. The type "D" curve is also produced by a cream having a crust however, the break-through is not so sharp which would seem to indicate a thicker crust. After the crust has been penetrated the curve again levels off or rises. In testing the unexposed soap- type creams, some rather interesting results were obtained. With no humectant present an "A" type curve of 0 slope was obtained. At 2% humectant glycerin gave an "A" type curve of 0 slope, propylene glycol an "A" type curve of 0.4 slope and sorbitol an "A" type curve of 0.9 slope indicating that TYPIGAL LOADING OURVES O•FA/NEO WIFtt ORUST MEASURING APPARATUS SNOWING EXAMPLE BAR GRAPH B k oR 1 INCneA SiNG PeNe rnA rio,v-• Figure 15

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)