THE EVALUATION OF A SHAMPOO and the first rinsing should remove practically all the dirt from the hair. The second application must produce a copious lather. (d) It must be easily rinsed out of the hair. (e) The hair must be clean and glossy and in good condition when dry. (f) The perfume must be pleasant throughout the operation. (g) There must be no scalp irrita- tion. For purposes of control. we can carry out only a limited number of shampoo tests to determine whether the shampoo is capable of filling these requirements. The shampoo when applied to one's own head can- not be used so effectively and easily as when it is applied by a second person, who is also better able to judge the cleanliness, gloss and general condition of the hair. It is therefore essentiM that the opera- tion should be carried out by some experienced person who would natur- ally be the one to make and record all the observations, with the excep- tion of such as (g). We have now to consider some variables in the working conditions. The most important is that all heads are not alike in their reaction to a shampoo. For example, greasy or dirty hair will tend to depress the lather of the first application and may even suppress it entirely. Not only so, but the very texture of the hair, whether fine or coarse, •511 affect lathering power. For this reason, when only a limited number of test shampoos can be carried out, it is desirable to divide the hair into two parts, left and right, down the middle line. One side is treated with a reference shampoo and the other with the one under examination. It must be observed here that, while we are by this means reducing a major cause of discrepancy, we are introducing a minor one. The positioning of the operator with reference to the two sides of the head makes it easier for him to manipulate one side than the other, and this is quite apparent at times, particularly when a fatigue effect develops in the course of the somewhat strenuous application of the shampoo. This disturbing factor is miniraised when each shampoo is used on an equal number of left and right sides. The saloon method is made more selective by diluting the shampoo before use with tap water to some arbitrary standard of concentration which may differ according to the purpose of the test. Very high con- centrations fail to show minor differences and may not reveal what we are really most concerned in finding, namely, whether a given shampoo is likely to fail to produce a lather on the first application in a significant number of cases, under the average variations in the condi- tions of customer usage. A useful level of concentration is around 0'25 per cent of active foaming agent or, if this should be difficult to assess, 0'5 per cent for a powder shampoo, 1'0 per cent for a 151

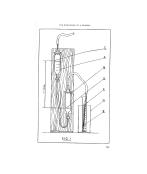

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS cream and 2 per cent for a liquid shampoo. The comparison of shampoos of different or unknown composition may conveniently be made at about the level of concentration indicated, bur adjusted to give solutions of equal cost. The lathering power can be ex- pressed in terms of the total volume of solution of the adopted concentra- tion required for the production of free lather on one average half head of hair in a first and a second applica- tion, with intermediate rinsing. A point of great interest is observed when a head chosen at random is submitted to a weekly quantitative shampoo with the same product. The volume of solution required will normally fall from week to week until in the fourth and succeeding treatments the amount used becomes constant. The saloon test is tedious and takes the time of two people for each unit of test a reliable judgment requires a number of tests to be carried out on different types of head, thus adding greatly to the cost of testing. It is imperative, therefore, to provide some simpler method of testing which will give results in agreement with the average of an adequate number of saloon tests on varied heads. Such a simplified test can then be used as a screen to eliminate unsatisfactory samples and materials from the more elaborate and costly saloon testings. Foaming power has been described as a vital criterion of shampoo value to the user, and for this reason a method of measuring foaming quality would be admirable as the screening device. Many tests of foaming power have been described from time to time, and an excellent rdsum• up to 1943 has been made by S. Ross, Ind. Chem., 15,329, 1943. A method will now be described in which variables incidental to such measurements are reduced to a minimum. The results agree well with actual shampoo tests carried out on the same samples. In Fig. I the apparatus is shown to include two 250 mi. cylindrical separating funnels with shortened stems which are joined by means of a length of rubber tubing. One funnel A, which forms an upper water reservoir, is supported so that a mark C indicating the level of 150 mls. of water in the funnel is about 17 inches above a reference mark D on the lower end of the second funnel B which acts as the low-level water reservoir. The lower funnel is fitted with a rubber stopper carrying a rubber connection to a 35 cm. stemmed sintered glass disc oe of porosity No. 1. The disc is placed in a 250 mi. graduated glass cylinder F, 1« inch in diameter, so that it faces upwards, resting on the bottom of the cylinder with the stem inclined diagonally in the cylinder. The cylinder'is placed in a wide glass jar G which acts as a water bath. In setting up the apparatus water is poured into the funnel B and sucked up into A, filling the rubber connecting tube completely and reaching the level of the 150 mi. 152

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)