J. Soc. Cosmet. Chem., 29, 237-246 (May 1978) Rheological properties of soap foam: I. apparatus for viscoelastic measurement on foam H. KOMATSU, H. YAMADA and S. FUKUSHIMA Shiseido Laboratories, 1050 Nippa-cho, Kohoku-ku, Yokohama,Japan 223. Received March 3 i, 1977• Presented at 24th Meeting, Society oj Rheology, October 1976, Maebashoe Gunma,Japan. Synopsis An apparatus was devised to measure the RHEOLOGICAL PROPERTIES of toilet SOAP FOAM. The prin- ciple of the measurement was based on the analysis of oscillation damped by foam. The MEASUREMENTS by this APPARATUS were conducted at about 2.5 Hz (cycles/sec) on the soap foams obtained from a 5% (wt/wt) toilet soap aqueous solution at 40øC. The diameter of each bubble remained about 100/x while the specific volume varied widely with varying condition of the preparation. The storage shear modulus increased from 500 to 850 dynes/cm", as the specific volume of foam increased from 10 to 25 cm:3/g. On the other hand, the dynamic viscosity was not much affected by the specific volume and was about 15 to 20 poise. The loss tangent, a parameter expressing energy dissipation, for the foams was calculated to be about 0.3. INTRODUCTION Foam is one of the dominant factors that determine the commercial value of such cos- metic products as soap, shampoo, shaving foam, cleansing foam, tooth paste, etc. For the purpose of offering those cosmetic products being favorably accepted by the consumer, it is necessary to evaluate various properties of foam such as foaminess, foaming capacity, foam stability and its mechanical properties. Among those properties, the mechanical property has been, to the best of our knowledge, rarely studied (1-4). The review in this area is given by Bikerman (5). The assessment of the mechanical properties of a products' foam has been mainly through sensory evaluation. For this reason, we attempted in our present work to devise an apparatus to measure the theological properties of foam. The principle of the measurement is based on the analysis of the oscillation of a coil spring damped by foam. This paper reports the design of the apparatus and the method of analysis, together with some experimental results obtained on toilet soap foam. 237

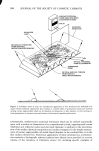

238 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS Figure 1. The photograph of the apparatus DESCRIPTION APPARATUS A photograph of the apparatus is shown in Figure 1. Figure 2 shows a schematic draw- ing of its principle parts. The top end of a coil spring was fixed, and a differential transducer core, an air bearing core, a solenoid core, a weight vessel and a disk were suspended in that order to the lower end. A foam sample placed in a measuring vessel was leveled up so as to come into contact

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)