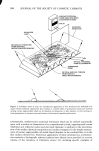

VISCOELASTIC MEASUREMENT ON FOAM 239 Coil spring Differential transducer Air bearing Solenoid Weight •Disk Foc•m Figure 2. Schematic drawings of principal parts of the apparatus with the disk (12 mm in diameter, 1 mm in thickness). A free oscillation ofagiven am- plitude and frequency was applied to the sample with the aid of the solenoid. The os- cillation damped by the sample was changed into an electrical signal. The signal taken from the differential transducer was passed to a transducer meter and, after amplifica- tion and filtration, was recorded by a recorder. At the same time, a period of the os- cillation was measured by a digital period meter. The air bearing was used to prevent the eccentric motion of the oscillating system's axis. An example of the oscillation damped by foam is shown in Figure 3 together with a control-free oscillation. The top pattern of the figure is without foam and the bottom pattern is with foam. The decrement of the oscillation was apparent with foam, however the oscillation was damped slightly even without foam. The decrement of the free oscillation, possibly caused by the viscosity of air, was taken into account when cal- culating the true decrement of the oscillation damped by foam. THE DEVICE FOR SAMPLE PREPARATION A commercial foam-generator (John Oster Manufacturing Co., Latherservice Ma- chine © ) was adapted by improving the following defects. First, we were unable to main-

240 JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS Fr• oscillation Damped oscillation time ( 5 sec. Figure 3. An example of the oscillation damped by foam, with control-free oscillation tain the solution at a constant temperature by the circulation of water at a constant temperature through a spiral glass tube inserted in the solution, we were able to solve this problem. Second, the machine motor's rotational frequency was hardly stabilized because of power insufficiency the motor was replaced by a powerful one. Third, the flow rate of a solution to the foam-generating part of the machine was variable using a tubing pump, a solution at a constant flow rate was injected. A 5% (w/w) toilet soap aqueous solution was foamed by the use of the improved ma- chine. Foam was taken into a measuring vessel that was then quickly transferred to the apparatus. The diameter of each bubble remained about 1001z whereas the specific volume of foams varied much with varying condition of the preparation. Water with a hardness of 70 ppm (as CaCOa) was prepared for use in our present work by dissolving calcium chloride in deionized water. THEORETICAL A mechanical model for the measuring system was assumed, as shown in Figure 4. The equation of motion for the model is given by Mse + Rk + (K + k)x = 0 [1]

Purchased for the exclusive use of nofirst nolast (unknown) From: SCC Media Library & Resource Center (library.scconline.org)